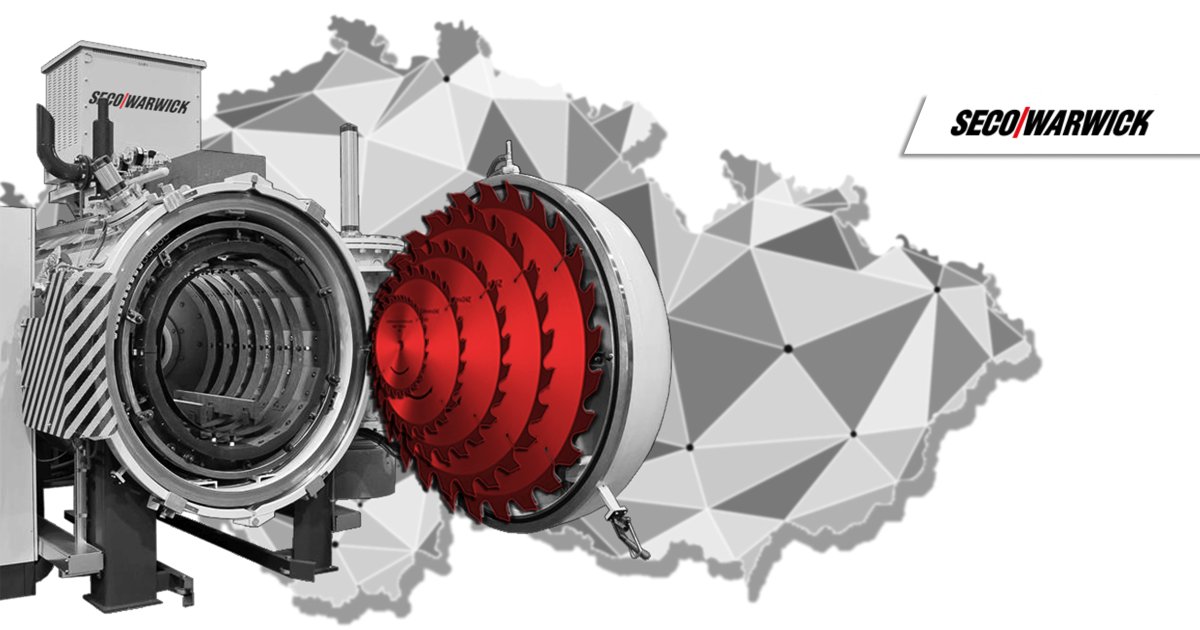

A renowned Czech manufacturer of machining tools, industrial knives, mulching knives, and chippers – Pilana Group – has placed an order with SECO/WARWICK for a Vector® vacuum furnace with 10 bar high-pressure gas quenching.

This is one of the Group’s flagship products and will be used for tool steel hardening and tempering processes. The design has been customized to enable the processing of long and straight items.

A furnace designed for processing knives and chippers

The furnace on order, based on a proven and reliable design — Vector —has been adapted to match the customer’s specific needs. SECO/WARWICK engineers have designed a unique working space with dimensions of 600x600x1800 mm. The device modification was implemented to fit the characteristic shape of the workpieces. Apart from the non-standard sizes of the chamber, the unit was equipped with a directional cooling option to effectively cool down long and thin knives that, due to their shape, are prone to distortion during the hardening process. With directional cooling, the goal is to reduce this undesirable phenomenon.

The furnace was customized to synchronize its operation to the dedicated thermal process for knives and chippers. The application for the device required an inverter that enables complete control over temperature at every stage of the hardening process to reduce distortion. With the additional option of directional cooling and the convection system, the system design helps to reduce the undesirable distortion significantly.

“The common goal was to reach an optimum matching of the furnace performance with the items processed by the customer. At SECO/WARWICK, we always build relationships and dialogue, making it possible to adjust our equipment to the customer’s particular needs. Employing outstanding and experienced engineers and having vast production expertise and a long-standing experience with furnaces intended for metal heat treatment, no solution would be impossible for us. Thus, we are renowned for customized designs of furnaces, perfectly matching the needs of our customers through technology originating from standard solutions,” — commented Maciej Korecki, VP, Vacuum Business Segment, SECO/WARWICK Group.

The Vector on order produces very efficient and clean hardening processes under an excellent vacuum thanks to a comprehensive pumping system. The efficient directional cooling system and enhanced safety of the hardening process are achieved using an inverter to provide better control over the temperature during the entire process.

A perfect Vector for the demanding Tool & Die industry

The Tool & Die industry is one of the most experienced groups in vacuum heat treatment. SECO/WARWICK delivered the solution that will work perfectly in this demanding environment thanks to its unique capabilities. The furnace supplied provides versatility and produces workpieces of outstanding quality.

“The SECO/WARWICK furnace will move the hardening process to a new level regarding controls, process design, and recording and archiving. With modern materials, the device is more efficient, saves energy, and is more reliable than it replaces. The new vacuum furnace will improve and increase the capacity of hardening and tempering processes and improve the process economy,” — said Maciej Korecki, VP, Vacuum Business Segment, SECO/WARWICK Group.