The solution for this manufacturer of heat exchangers for agricultural machinery, construction vehicles, ships and power generators, will be intended for brazing heat exchangers and will significantly increase the manufacturer’s efficiency in the production of large-size heat exchangers for trucks.

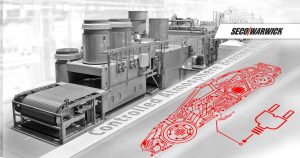

The SECO/WARWICK controlled atmosphere brazing (CAB) line on the order will consist of a thermal degreaser, a wet fluxer, a dry-off oven, radiation braze furnace, air-jacketed cooling chamber, and a final cooling chamber. The entire system will be equipped with a dedicated control system.

Many companies in the Chinese market have a similar solution, which significantly increased their production capacity. Ordering the CAB line by a customer from the same market means that the equipment fulfills its role perfectly, having a very good local reputation.

The furnace delivery is scheduled for July this year.

CAB technology is developed for heat exchanger production

Aluminum Controlled Atmosphere Brazing (CAB) is the first choice technology in aluminum heat exchanger production in the automotive industry.

“We are one of the leading manufacturers of systems for brazing heat exchangers. Thanks to the efficiency of our systems, manufacturers of heat exchangers for passenger cars, vans, agricultural machines or power generators choose our products. When it comes to the automotive industry, the heat exchangers produced in our solutions supply all of the world’s leading automotive suppliers. We have developed proprietary CAB lines that perfectly meet the market’s needs,” says Piotr Skarbiński, Vice President of SECO/WARWICK’s Aluminum and CAB Products Segment. “Our specialized lines for brazing in CAB technology (Controlled Atmosphere Brazing) are also used for the HVAC industry – air conditioning and refrigeration, to significantly reduce CO2 emissions, reducing environmental and climate warming costs, which is now a huge advantage that allows customers to actually reduce the costs of manufacturing”, adds P. Skarbiński.

“We have been observing the SECO/WARWICK offer on the Chinese market for several years. We know that many leading radiator manufacturers use this manufacturer’s aluminum brazing solutions. Bearing in mind the impeccable company reputation, we decided to choose a proven supplier. That is what SECO/WARWICK is like, and through its technology, SECO/WARWICK will help us increase production and improve its efficiency. The key to the success of this particular solution is efficiency, reliability and repeatability of the process at each time throughout the 24/7 operating cycle. In my opinion, in the field of aluminum brazing equipment on the Chinese market, SECO/WARWICK is the first choice company, ” explains Wenchao Xing, Chairman Jiangsu RIDEA.

SECO/WARWICK in China

SECO/WARWICK China, as a branch, has been operating in the Chinese market since 2010. First, it offered equipment for controlled atmosphere aluminum brazing. During 12 years of operation in this market, SECO/WARWICK has sold a large number of CAB lines used for the production of various types of heat exchangers.

The company has an excellent reputation in China.

Jiangsu RIDEA Technology Co., Ltd. also has a well-deserved impeccable reputation. The company specializes in the design, production, sale and service of heat exchangers for various engines. Its flagship products include radiators, intercoolers and oil coolers. The products are used in power generators, construction machines, agricultural machines, cars, ships, or equipment used in the energy industry. The annual production capacity of aluminum and copper heat exchangers amounts to 300,000 units. Most of the production goes to the local market. Jiangsu RIDEA, just like SECO/WARWICK, follows a business philosophy based on honesty, teamwork, efficiency and innovation.