R&D CAB Brazing Center

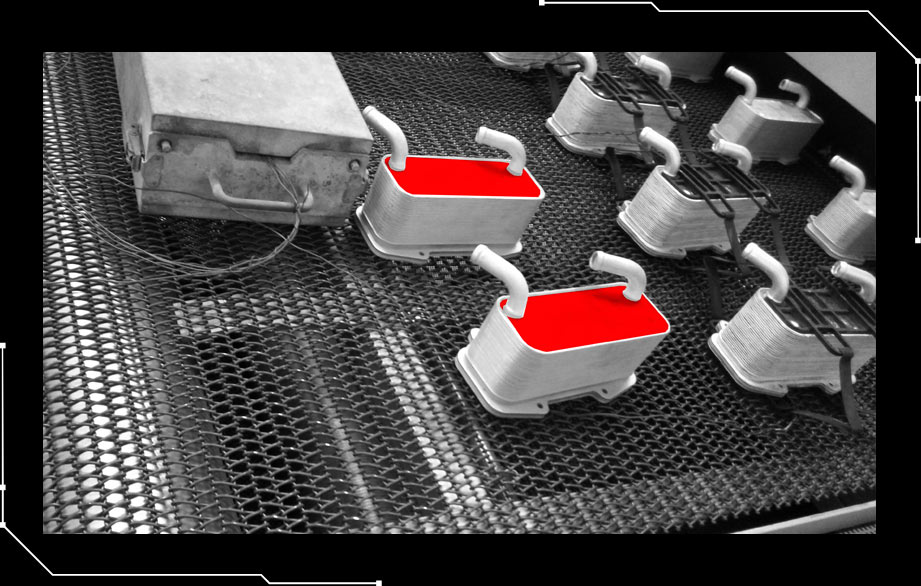

SECO/WARWICK operates a fully equipped CAB Brazing Center to support customers by allowing them to run trials and prototypes of a wide variety of heat exchangers for all applications and industries including automotive, energy, HVAC&R, and electronics.

REDUCE YOUR INVESTMENT RISK BY TAKING

ADVANTAGE OF THE SECO/WARWICK CAB BRAZING CENTER

- The Center can then model and document complete process information and control recipes for your production requirements.

- The Brazing Center can perform double duty as a center for employee training. Customers may also purchase furnace time to run production on a cost-plus basis.

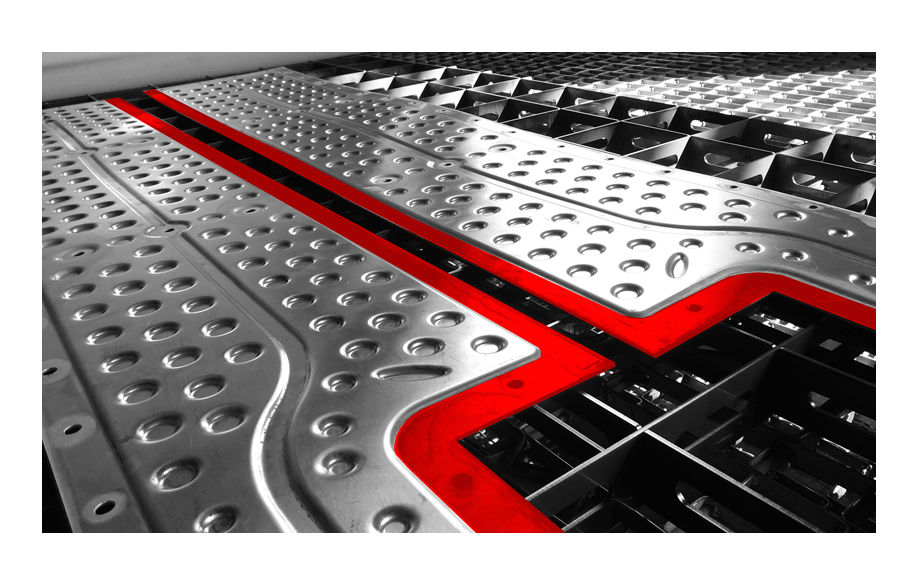

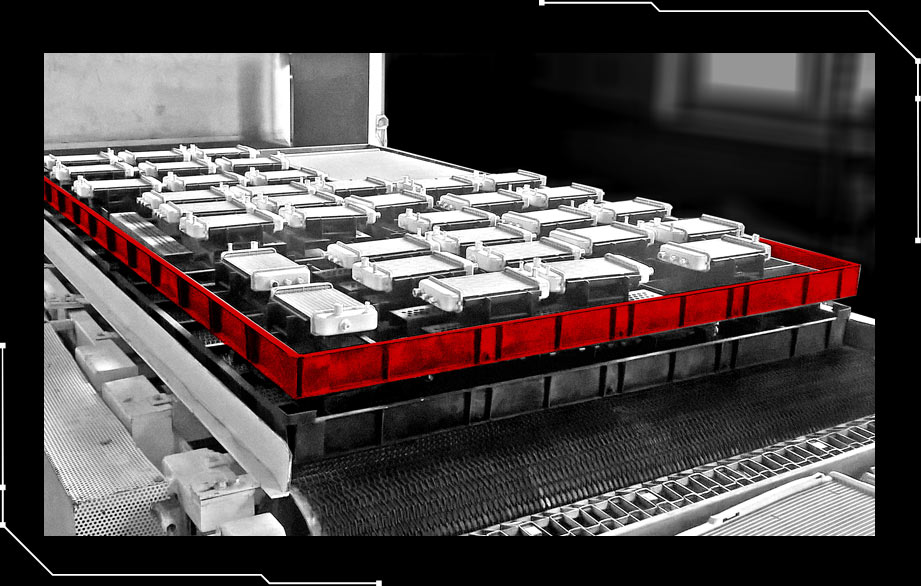

The R&D CAB Brazing Center is fully equipped with an Active Only® CAB Brazing system, manual wet fluxer, and thermal degreasing / drying / debinding / oven to allow customers to utilize a complete, operational manufacturing cell.

The CAB furnace can handle loads up to 1500 mm wide x 2500 mm long x 450 mm high.

The Active Only® CAB furnace offers these unique process benefits for all types of cores:

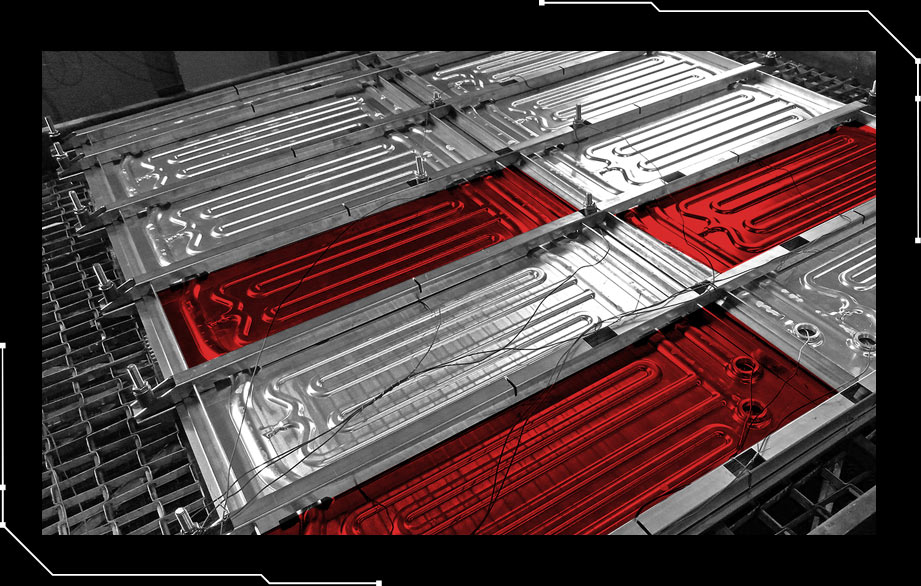

- The semi-continuous process configuration allows us to heat and cool even very large parts such as battery coolers.

- Convection heating reduces cycle time.

- Uniform temperature throughout the braze area improves braze quality.

A sharper temperature profile provides accurate process control.

Reduce your investment risk by taking advantage of R&D CAB Brazing center!

Will it be possible to monitor the process parameters in real time?

Yes, our CAB R&D is equipped with a device that records batch temperature with a telemetry function, which allows the system to perform real-time monitoring and temperature control.

How should the batches be prepared for brazing tests.

To fully utilize the available time, the batches should be cleaned of oil, fluxed and assembled together with the instrumentation. We can also carry out these operations together before the tests, but this is associated with a limitation of the time available for the brazing tests themselves.

How long does one process take?

On average, about 2 hours should be assumed for one test. The brazing itself takes from 10 to 30 minutes. However, the total time of the run through the R&D furnace, the time needed to prepare the batch, and the time needed to analyze the test result and any corrections to the next test parameters must be taken into account.