WE CREATE THE METALLURGY AND HEAT TREATMENT WORLD

R&D centers

performed processes

completed projects

services offered

patents

partner universities

COMMERCIAL HEAT TREATMENT AND METALLURGICAL SERVICES AND R&D RESEARCH

Do you want to discover research and development services that will increase your distance from competitors?

GET UNIQUE KNOWLEDGE

Uncover the expert content

CLOSE COOPERATION

WITH SCIENCE

DEFINED SOLUTIONS

FOR YOUR REQUIREMENTS

5 reasons to use R&D services

TECH SPOT LIGHT

Experts from the SECO/WARWICK Research and Development Center share their knowledge about the technological solutions available at the R&D Center.

YOUR DEFINED

TECHNOLOGY

What processes can the SECO/WARWICK Group’s R&D department perform?

- CAB (Controlled Atmosphere Brazing) – aluminum brazing in a protective atmosphere.

- VAB (Vacuum Aluminum Brazing) – aluminum brazing in vacuum.

- Vacuum brazing at a vacuum level of 1×10-5

- LPC (Low Pressure Carburizing) – vacuum carburizing in the temperature range of 860-1150°C using four mixtures of process gases and working pressures in the range of 0.1 ÷ 10 mbar with the possibility of performing the PreNit operation (400 ÷ 700°C) with the option of:

- gas hardening (15 bar abs N2),

- hardening in any hardening oil (up to 5 kg of load).

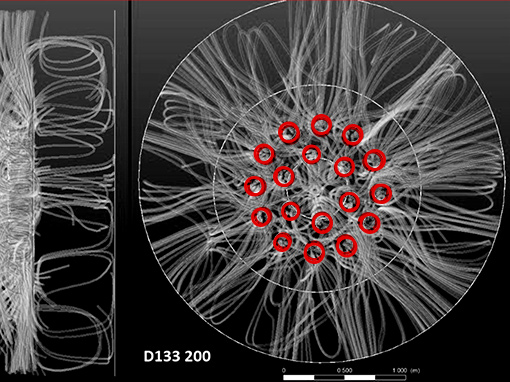

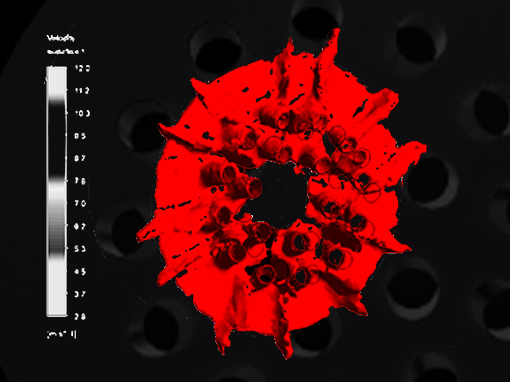

- SPF (Single Piece Flow) – vacuum heat treatment and LPC vacuum carburizing of single parts in a flow system with 4D Quench® gas hardening for dedicated round elements (gears, bearing raceways, etc.).

- LPCN (Low Pressure Carbonitriding) – vacuum carbonitriding.

- LPN (Low Pressure Nitriding) – vacuum nitriding in the gas nitriding temperature range.

- HTSN (High Temperature Solution Nitriding) – high temperature nitriding.

- Gas nitriding using the ZeroFlow method.

- Gas nitrocarburizing with regulation of the complex atmosphere potential – carbon-bearing atmosphere based on any gas, i.e. CH3OH, CO, CO2.

- Pre- and post-oxidation.

- Heat improvement and hardening in gas (15 bar abs N2) with the possibility of final vacuum nitriding – at the R&D testing station.

- Heat improvement and hardening in quenching oil or polymer medium (any) up to 5 kg of loads – at the R&D testing station.

- Comprehensive normalization, i.e.

- with allotropic transformation: homogenizing, complete, incomplete, normalizing, with isothermal transformation, spheroidizing, pearlizing, graphitizing, bright,

- without allotropic transformation: stress relieving, recrystallizing, stabilizing.

- Solution heat treatment and aging.

- VIM (Vacuum Induction Melting):

- EC (Equiax Casting),

- DS (Directional Solidifcation),

- SC (Single Crystal Casting).

What kind of metal product testing services does SECO/LAB offer?

In the SECO/LAB laboratory, we have the necessary equipment for metallographic preparation of ferrous and non-ferrous metals. We offer microstructure tests using a light microscope, equipped with a high-resolution camera with a maximum magnification of up to 1000x. Moreover, we carry out hardness tests using the most common methods (Vickers, Rockwell, Brinell, Knoop), with a very wide range of loads, which means that we have a wide range of testing capabilities.

What is the reliability of the research results?

In the SECO/WARWICK Group’s R&D laboratory, tests are carried out by qualified and experienced staff consisting of engineers, technologists and specialists in material science and heat treatment. We also cooperate with scientific units with which we consult about solutions, technologies and processes.

All tests are carried out in accordance with technical standards, and the furnaces are regularly calibrated by entities accredited in this field. Each furnace is checked to ensure it meets the established quality standards and complies with a defined startup procedure before measurement.

What do research and testing services involve?

- We design technological processes using advanced computer tools

- We complete the results of activities in comparison with previously known requirements

- We carry out analyses, draw conclusions and formulate suggestions

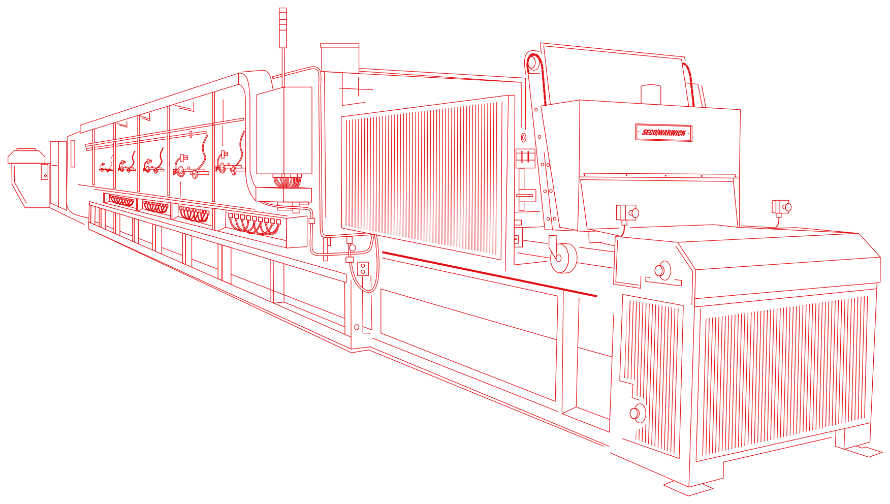

- We perform tests and services on full-scale industrial equipment

- Each heat treatment process is verified metallographically

- We control the heat treatment process at every stage

- We use extensive experience and databases

- We prepare a comprehensive research report taking into account all of the customer’s needs

- We adapt (and select) the technological process based on the results

We guarantee operational efficiency and full data archiving |We ensure research transparency| Confidentiality clause applies

For which industries does the SECO/WARWICK conduct research at SECO/LAB?

- Aviation

- Automotive

- Medical

- Service

- Energy

- Mining

* – There is no industry in which there is no heat treatment, at least indirectly.

Do you have to be a SECO/WARWICK customer to order research?

We are open to every person, institution, and company.

Our activity has shown that we are able to successfully complete projects both with large companies and with individual people related to the heat treatment industry. We have successfully completed hundreds of projects, performing thousands of technological processes on dozens of furnaces.

The shortest project lasted a week, and the longest lasted 5 years.

The shortest process took less than 1 hour, and the longest took 5 days.