Developed by SECO/WARWICK – one of the world’s leading manufacturers of heat processing equipment and a technology leader

With our fully equipped research and development facility and cooperation with the academic centers in Europe, we are able to provide innovative solutions not ofered anywhere else in the world. The Group is made up of companies located in five countries on three continents, and We sell our products Worldwide. We supply our equipment to customers involved in steel, titanium and aluminum production as well as aluminum recycling, forging, automotive, aerospace, commercial heat treating, HVAC/R, electronics, Wind energy, medical equipment and nuclear industries.

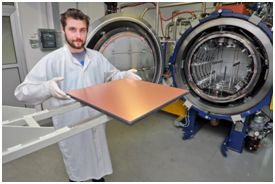

For wide range of industrial and R&D applications

- Working temperature up to 1200°C

- Substrate formats up to 500 x 500 mm (larger reactors on request)

- Ability to load multiple levels of substrate in one batch

- Growth ofgraphene on 3d objects

- Flexible control system and intuitive HM

Flexible equipment

- Large formats and/or small samples can be processed

- Different gasses and mixtures can be used

- Process can be conducted in vacuum / partial pressure and positive pressure (from 10′; Torr to 1,5 bar absi)

- Variable process temperature and heat-up rate

- Variable cooling rate in vacuum, still atmosphere or accelerated atmosphere

FIND OUT MORE: https://www.secowarwick.com/en/purification-of-graphite-materials/

|

|

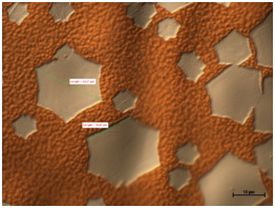

Optical microscope image of graphene layer grown on Cu foil, transferred on to SiO2 substrate shows continuous layer without cracks, holes, etc.

|

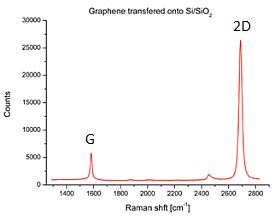

Electrical parameters have been measured based on Hall effect in Van der Pauw configuration at RT over 1cm x 1cm samples of graphene transferred onto Si/SiO2 substrate.

- high carrier concentration:

p= 1,257E13

µ= 1148

ρ= 433

- low carrier concentration:

p= 2.393E12

µ= 1771

ρ= 1476

where:

p- sheet hole concentration [cm-2]

µ- carrier mobility [cm2/V·s]

ρ- resistivity [Ω·cm]