OVERHAUL AND UPGRADE OF FURNACE HEATING CHAMBER

Increase the efficiency of your furnace by hot zone replacement!

Replacement & Rebuilding of Hot Zones

Replacing of a furnace heating chamber (hot zone) is eco twice over: it’s both economical and eco-friendly.

The heating chamber plays an important role in systems for metal heat treatment. Its condition determines the general performance of the overall equipment, power consumption and temperature distribution, which all affect the final quality of the treated objects. Therefore, the hot zone is frequently considered the heart of the entire system.

Heat treatment furnaces for metals are characterized by their long lifetime. However, an incorrect furnace maintenance schedule, improper use of the furnace or simply wear and tear can all contribute to a failure and thus a decrease in furnace efficiency. When the heating chamber is worn out, it is necessary to replace or repair it.

Replacement of the heating chamber guarantees:

/ Trouble-free operation of the furnace,

/ Better temperature distribution,

/ Increased process cleanliness,

/ Limited heating power losses

/ Better heating efficiency and safety.

The knowledge, skills and experience of SECO/WARWICK’s experts will make your equipment operate more effectively and more efficiently.

SECO/WARWICK is one of the industry’s most experienced manufacturers of vacuum furnaces specializing in hot zone replacement along with an entire portfolio of technical services. Let SECO/WARWICK deliver your next hot zone for ease of installation, a smooth start-up and worry-free production.

HEATING CHAMBER

upgrade, replacement, overhaul, repair.

We offer upgrades and comprehensive overhauls of heating chambers, both for SECO/WARWICK equipment and for equipment made by other manufacturers. Overhauling or upgrading a furnace heating chamber not only ensures the smooth operation of the furnace but also guarantees safety and savings.

HOT ZONE TYPES

SECO/WARWICK is an expert at providing replacement components and fabrications to meet your maintenance needs. Key to efficient vacuum furnace operation is a hot zone that meets advanced technical standards for optimum furnace performance.

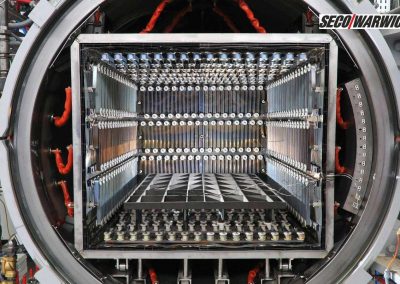

SECO/WARWICK can provide replacement hot zones and heating elements for a wide variety of furnaces sizes and brands ranging from the smallest lab furnace to large scale capacity equipment. Configurations are available in both graphite and molybdenum. Each hot zone is produced with the highest quality materials and flawless workmanship.

/CONSIDERATIONS FOR THE OVERHAUL OF VACUUM FURNACE HEATING CHAMBERS

- the housing of the heating chamber together with its insulation,

- heating element supports together with the heating elements,

- heating chamber hatches operating in the cooling phase,

- process gas nozzles,

- load supports together with the insulators.

Taking into account all these elements working together, we know they determine the quality of the heat treatment process, therefore, can we say that an overhaul of the vacuum furnace heating chamber is trivial?

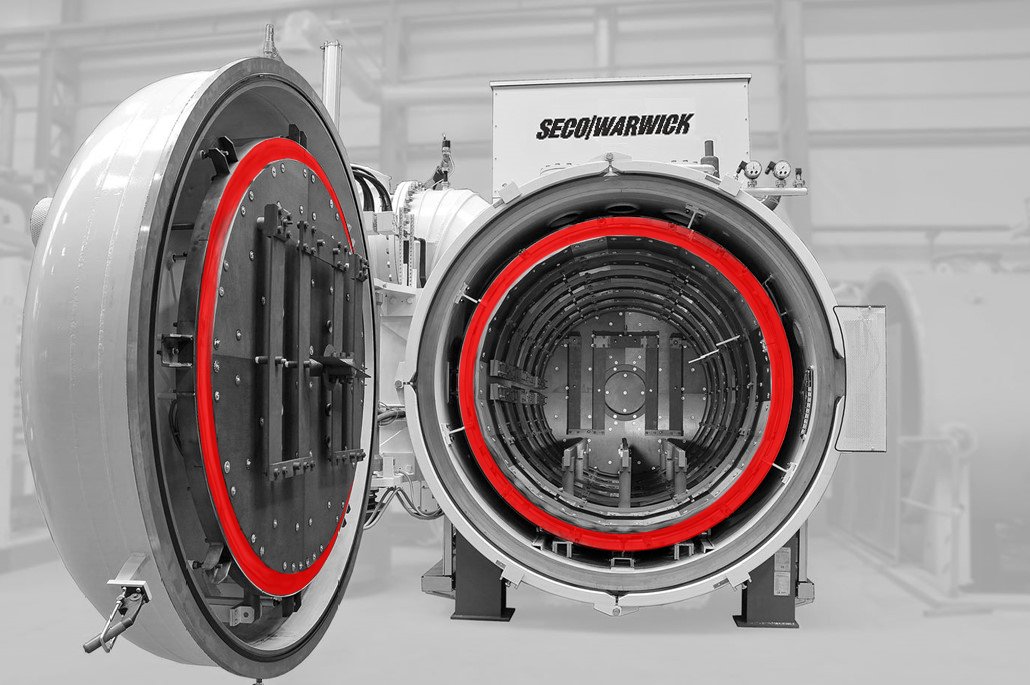

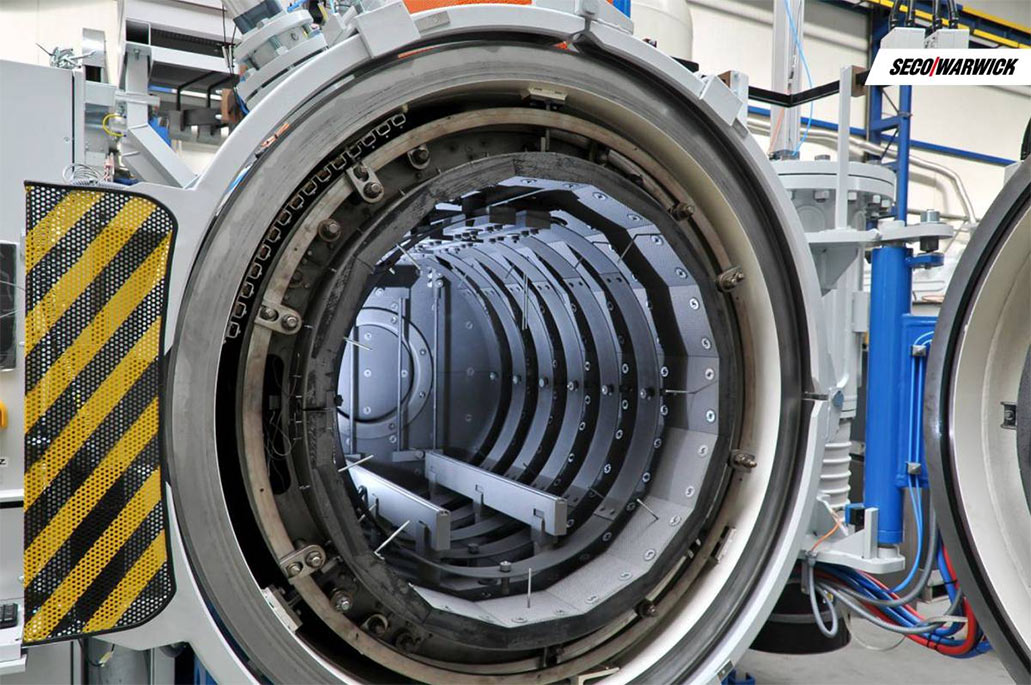

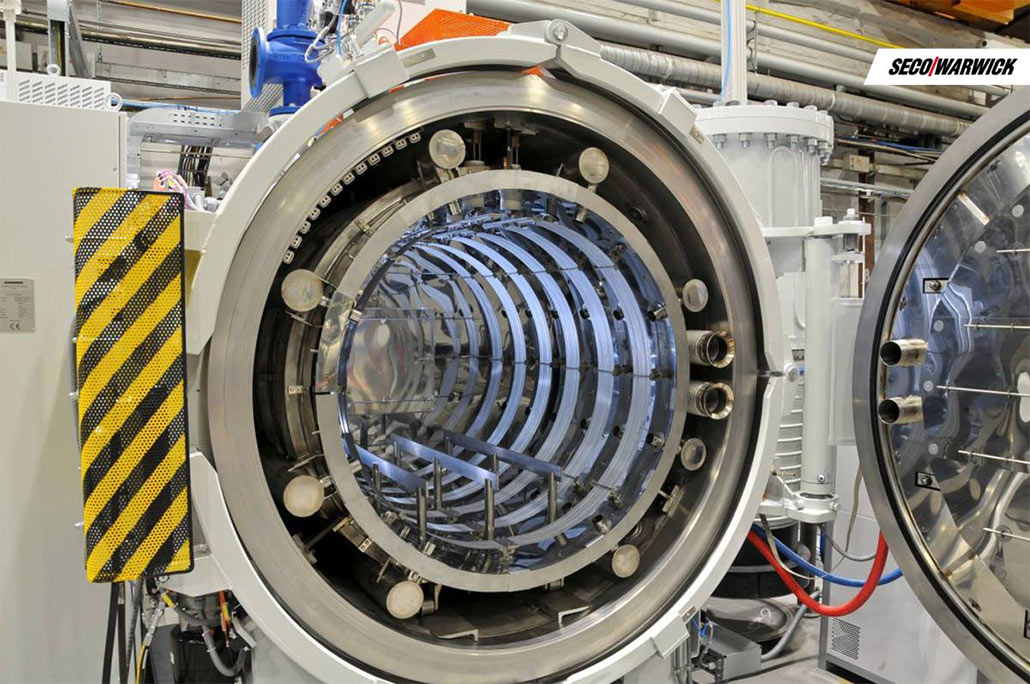

Let’s start with just the housing. There are two basic structures with a circular cross section, one operating horizontally and/or vertically, and the second, a rectangular configuration.

Next, we have insulation. Here we are entering a minefield, as there is no single correct solution. Depending on the shape of the chamber, the maximum operating temperature, the required temperature distribution, and the expected oxygen purity, different solutions are possible, made with the use of soft and/or hard graphite insulation, including graphite foil, or solutions based on screens of stainless and molybdenum sheet. There are also mixed combinations, combining metal and ceramic insulation. The insulation acts as a thermal barrier not only affecting the loss of heat through the housing, and thus the economics of the process, but also the temperature distribution. The selected material and assembly method will also play a significant role in the rate of evacuation of the entire furnace, in other words degassing, and at least partially the maximum vacuum.

Selecting heating elements entails just as many possibilities. We may choose from among tubular, flat, straight or bent graphite elements, and molybdenum heating elements. Associated in a three-phase wye or delta power system, and sometimes in single-phase systems, combined in a whole, they must have an appropriate resistance that is also homogeneous over the entire length of such a set. Incorrect execution can lead to non-homogeneous heat radiation, which can in turn make it impossible to achieve correct temperature distribution. It is also important to remember that the resistance of the entire system changes as a function of temperature. The system must therefore correspond to the originally designed parameters of the power transformer supplying heating elements with energy. Joints are exposed to vibrations and loosening, which increases resistance locally and can result in excessive overheating and damage.

Depending on the furnace manufacturer, the shape of the hatches and the way they work can vary; many solutions are patented. Here, precise mapping is required, as hatches are one of the key elements of the cooling system and can critically affect the quenching results.

If the furnace is equipped with options for working with process gasses, for example in carburizing or nitriding processes, there will additionally be elements of the internal gas system, which must also be properly installed on the housing of the chamber and passed through the insulation into its interior.

Preparing new supports causes the fewest problems, though mistakes can be made here too, by not properly selecting materials, their dimensions, and the structure of insulation between the supports and the batch tray/basket.

- Pumping time, degassing – the type of insulation materials used and the method of assembly (and, of course, the entire pumping system, which will not be discussed here),

- Uniformity of temperature distribution – the design of the heating chamber, the type of insulation materials used, the type and method of assembly of heating elements, the quality of execution,

- Cooling speed – correct mapping or a new design and the quality of the hatches (and, of course, the entire cooling system, with a blower and an exchanger, which will not be discussed here),

- Heat losses – a mapping of the original design, the type of insulation materials used, and the method of their assembly.

Looking at all of these interdependencies, the heating chamber overhaul should not be treated as an easy matter. Many manufacturers of heat treatment equipment focus solely on overhauls of their own chambers. This is mainly related to access to the original documentation and, very often, materials.

SECO/WARWICK is one of the few companies that successfully undertake overhauls of chambers from any manufacturer. In 2020 alone, we carried out more than 20 such services, bringing back to life furnaces, not only of our own production, but also of seven other world-class manufacturers. Significantly, our customers are so satisfied with these services that they are already asking about further overhauls and modernisations. This is partly due to the fact that SECO/WARWICK has always set the bar high for itself. We are one of the few companies that take on the truly toughest jobs, and we specialise in manufacturing custom-order equipment that is perfectly suited to the extremely specific and strongly individual needs of our customers. Statements such as these can be read in many a marketing material, but in the case of SECO/WARWICK, it is written into the company’s DNA.

The SECO/WARWICK Group has established a separate company, SECO/WARWICK Services, whose object is to provide after-sales service to our customers, including overhauls of vacuum furnaces, and in particular of heating chambers. We provide technical assistance with analysing the condition of equipment and appraising the work, design and overhaul. Should such a need arise, we can analyse the potential to modernise and improve the selected parameters.