HYDRAULIC PARTS

ENGINE PARTS

FUEL INSTALLATION

TURBINE BLADES

JET ENGINE PARTS

LANDING GEARS

ELECTRICAL STEELS

CASTINGS

STEEL

SKINS AND COMPONENTS

WIRE

PROFILES

FOILS

HEAT EXCHANGERS

GEARS

SHAFTS

DRILLING EQUIPMENT

PUMPS

WIRE

MACHINE PARTS

ELECTRIC POWER GENERATORS – RADIATORS

HEAT EXCHANGERS

HEAT EXCHANGER – DRY CONDENSING TUBES

HVAC

RADIATOR

HEATER

EVAPORATOR

CONDENSER

OIL COOLER

CHARGE AIR COOLER

CASTING MATERIAL INTO FINISHED FORMS, CREATING NEW ALLOYS

GEARS

GEAR SHAFTS

ENGINE COMPONENTS OF COMBAT AIRCRAFT

CUTTING TOOLS

FORGING DIES

DIES FOR EXTRUDING ALUMINUM PROFILES

DIE INSERTS

SCREWS OF PLASTIC INJECTION MOLDING MACHINES

MOLD PARTS FOR ALUMINUM CASTING

PRESS MOLDS

FORMING FITTINGS

NAILS

BOLTS

NUTS

SCREWS

STAMPS AND PADS

DIES FOR EXTRUDING PROFILES

COINS AND PADS

STAMPS AND DIES

FORMING FITTINGS

ADDITIVE MANUFACTURING

MACHINE PARTS

HYDRAULIC PARTS

LARGE GEARS

AIRCRAFT ENGINE

GEARS

LANDING GEARS

STEEL ELEMENTS

HEAT EXCHANGERS

COILS

CASTINGS

WIRE

BOLTS

HEAT EXCHANGERS

GEARS

BATTERY COOLERS

FUEL INJECTION NOZZLES

TOOLS & DIES

PROFILES

SHEET

FASTENERS

FOILS

STEEL

BEARINGS

IMPLANTS

SURGICAL INSTRUMENTS

VEIN CLEANING TUBES

SUPPLIER

VARIOUS INDUSTRIES

DIFFERENT TECHNOLOGIES

AVIATION

We cooperate with almost all the major players in the aviation sector. One could say that SECO/WARWICK has its modest share in the vast majority of passenger aircraft production. For this industry, we provide solutions for the manufacture of plane engine blades, heat exchangers, turbine blades, aluminum coatings, landing gears, and brakes, fasteners and other critical components.

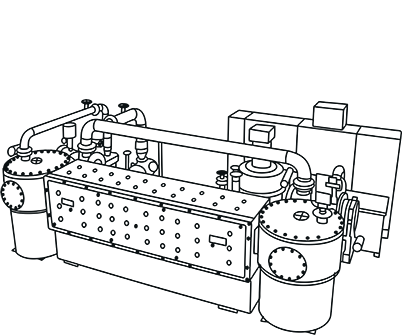

POWER INDUSTRY

The power industry is the fourth key customer for SECO/WARWICK Group’s equipment. The power industry uses metalworking furnaces To manufacture dies, tools, heat exchangers, and pipes. Though gas turbines are a mature technology, there is always room for improvement. SECO/WARWICK’s solutions help to manufacture Plate & Bar heat exchangers, aluminum heat exchangers for air conditioning and the refrigeration industry, along with exchangers for condensing water vapor. We actively participate in projects related to renewable energy sources.

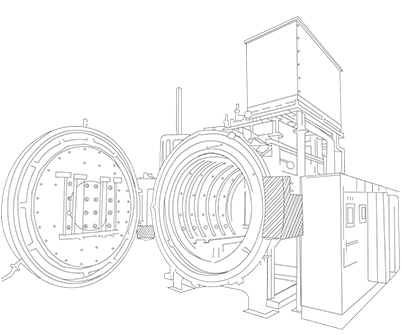

DEFENSE INDUSTRY

The defense industry is a very demanding partner that expects absolute discretion. SECO/WARWICK works for many national military corporations. For this industry, we provide solutions for the production of aircraft engine blades, heat exchangers, turbine blades, aluminum coatings, armor plate, elements for space suits, and landing gear, along with brakes for combat, reconnaissance, and transport aircraft, as well as devices for the production of other military equipment.

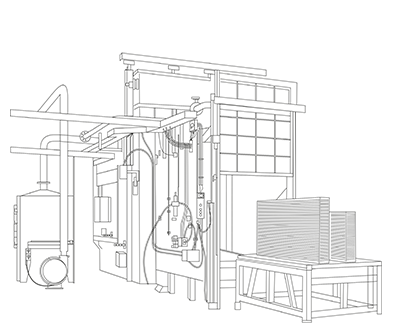

TOOL & DIE INDUSTRY

Thanks to SECO/WARWICK equipment, knives, sleeves, drills, cutting tools, fasteners, dies, and tools for tire production are created. Often, these clients require a fundamental benefit – high uniformity of parts subjected to heat treatment – this processing technology solves many distortion problems that in turn enables users to reduce downstream processing costs.

Due to the number of machined parts, repeatability, cleanliness, and final detail quality are extremely important for this customer. SECO/WARWICK also ensures the reliability of equipment and the continuity of production, which is crucial for the tool & die industry.

MINTING INDUSTRY

Mints are very demanding clients who carefully scrutinize the technologies used in the production of coins, numismatics, medals, or stamps. They produce products of very high quality, which must be excellent in terms of details and production repeatability. These clients often need equipment that significantly increases production efficiency and offers the highest possible quality and, from the buyer’s perspective, significant durability. Mints are very specific companies that often cannot resort to commercial heat treatment, so it was extremely important that the equipment powering them is of the highest quality.

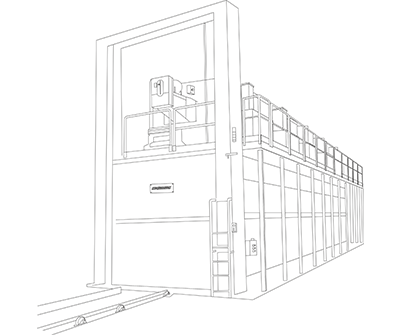

COMMERCIAL HEAT TREATMENT

Service hardening plants are one of SECO/WARWICK’s main partners who we have been working with for decades. Our equipment operates As the machinery of both large commercial hardening plants and smaller local operators. To this industry, operational efficiency Characterized by shorter production cycles and low production costs is crucial. Powered by SECO/WARWICK’s equipment, commercial service hardening plants process tools and dies, gears, pipes, heat exchangers, jet engine components, gas turbine parts, and fuel systems, to name just a few of the components that require heat treatment.

AUTOMOTIVE INDUSTRY

The automotive industry uses heat treatment to manufacture gearwheels, bearings, shafts, rings, and bushings. The most important thing for this industry is the reliability of the solutions, their efficiency, and repeatability of processes. Therefore, solutions proposed to this industry must consider the need to reduce deformations, lower process costs, shorten the cycle time, apply effective and efficient carburization, and reduce CO2 emissions.

MEDICAL INDUSTRY

The high-tech medical industry is one of the most demanding in terms of standards, procedures, and technical parameters that devices involved in the production process must meet. Complex medical equipment components like RF components or components for X-ray lamps, must be characterized by maximum precision, as they are involved in processes that determine not only the quality of treatment, but also human life. Therefore, medical equipment manufacturers, when choosing equipment, prioritize quality, reliability, and experience. SECO/WARWICK supplies furnaces for many medical corporations. This equipment proves itself in the production of surgical tools, X-ray equipment, orthopedic prostheses, life-saving equipment, as well as in production utilizing 3D printing applications.

DISCOVER TECHNOLOGIES FOR YOUR INDUSTRIES

HOW INDUSTRIES USE OUR TECHNOLOGIES

EXPLORE MORE

Don’t miss the chance to uncover the secrets of our app and explore the dynamic world of industrial solutions, dedicated for various industries.

What are the industries where the SECO/WARWICK Group supplies its industrial furnaces?

We provide solutions to leading industries worldwide. 70% of SECO/WARWICK solution recipients are demanding industries and globally recognizable brands. Strategic industries for our Group include automotive, energy, aviation, defense, machinery, tooling, medical, minting, and construction.

What solutions are most frequently used by commercial heat treatment shops?

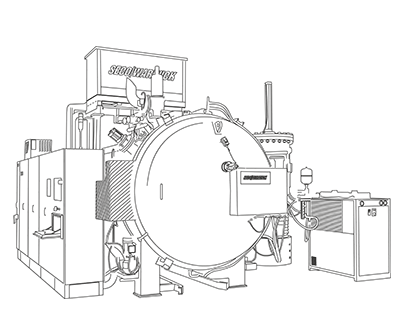

SECO/WARWICK equipment powers machine parks both in global metal heat treatment plants and smaller, local commercial heat treatment shops, or partners opting for in-house processing. The most frequently chosen products are Vector furnace lines, dual- and triple-chamber vacuum furnaces from the CaseMaster Evolution line, as well as ZeroFlow® gas nitriding furnaces with vacuum purging. This equipment offers operational efficiency characterized by low production costs, and the elimination of production downtimes – crucial for this industry. In commercial heat treatment shops, SECO/WARWICK equipment provides a wide variety of process options for metal heat treating. Typical applications include tools, dies, gears, tubes, heat exchangers, jet engine components, gas turbine parts, and fuel installations.

What types of products are processed in SECO/WARWICK industrial furnaces?

We collaborate with almost all major players in the aviation market. It can be said that SECO/WARWICK modestly contributes to the vast majority of passenger aircraft production companies. For this industry, we provide solutions for the manufacturing of aircraft engine blades, heat exchangers, turbine blades, aluminum coatings, landing gear, and brakes.

What is essential in heat treatment for the automotive industry?

What is most important for this industry is the reliability of solutions, their efficiency, and the repeatability of processes. Therefore, solutions addressed to this sector must consider the need to reduce distortions, lower process costs, shorten lead times, achieve effective and efficient carburizing results, and reduce CO₂ emissions.

How are SECO/WARWICK industrial furnaces utilized in the energy industry?

Energy utilizes metal heat treatment furnaces for the production of pipe, wire, profiles, heat exchangers, power generators, and gas turbine blades. SECO/WARWICK solutions help produce Plate & Bar heat exchangers, aluminum heat exchangers for the air conditioning and refrigeration industry, and steam condensation heat exchangers. We actively participate in projects related to renewable energy sources.

Does the medical industry utilize heat treatment?

The high-tech medical industry is one of the most demanding in terms of standards, procedures, and technical parameters that devices involved in the production process must meet. Medical equipment manufacturers, when choosing equipment, prioritize quality, reliability, and experience. SECO/WARWICK’s solutions prove themselves in the production of surgical tools, X-ray equipment, orthopedic prostheses, and life-saving equipment, as well as in production utilizing 3D printing applications.

Why do mints use industrial furnaces?

Mints use industrial furnaces for the production of coins, numismatics, medals, or stamps. They produce products of very high quality, which must be excellent in terms of details and production repeatability. These clients often need equipment that significantly increases production efficiency and offers the highest possible quality and, from the buyers’ perspective, significant durability.

Is the defense industry a recipient of heat treatment and metallurgy solutions?

The defense industry is a very demanding partner that also expects absolute discretion. SECO/WARWICK works for many national military corporations. For this industry, we provide solutions for the production of aircraft engine blades, heat exchangers, turbine blades, aluminum coatings, armor plate, elements for space suits and landing gears along with brakes for combat, reconnaissance, and transport aircraft, as well as equipment for the production of other military equipment.

Tooling Industry And Heat Treatment

In SECO/WARWICK equipment, heat treatment is applied to knives, sleeves, drills, cutting tools, fasteners, dies, and tools for tire production. Often, these clients require a fundamental benefit – high uniformity of parts subjected to heat treatment, which solves distortion problems experienced using various technologies. Due to the number of machined parts, repeatability, cleanliness, and final detail quality are extremely important. SECO/WARWICK also ensures the reliability of equipment and the continuity of production, which is crucial for the tool & die industry.