Retech launches an ultra-fast induction furnace (VIM) for the Serbian foundry, Livnica Preciznih Odlivaka.

The global supplier of vacuum metallurgical furnaces, Retech part of the SECO/WARWICK Group, is completing an order with the Serbian foundry, Livnica Preciznih Odlivaka. At the beginning of the year, the final performance tests of the new equipment were carried out....

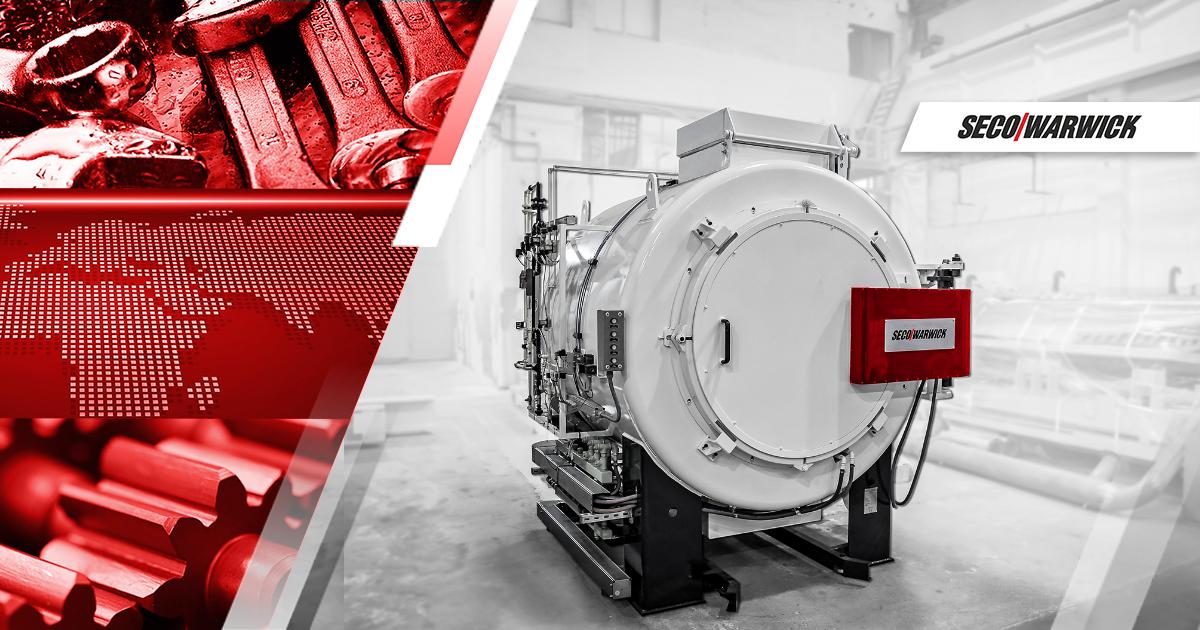

READ MORESECO/WARWICK Group secures an order for a large pit gas nitriding furnace from a North America

This will be one of the largest pit furnaces that SECO/WARWICK has ever built. The customer chose SECO/VACUUM (SVT) because of the Group’s extensive experience and industry leadership in gas nitriding and ferritic nitrocarburizing process development, its R&D...

READ MORESECO/WARWICK to build a 12-metre vertical retort furnace for the Karlsruhe Institute of Technology

The SECO/WARWICK vertical vacuum retort furnace for the Karlsruhe Institute of Technology (Germany) will be used for high-vacuum annealing of gyrotron components. The equipment will be used as part of the ITER project. This is the first time the SECO/WARWICK Group...

READ MORERetech – a global supplier of vacuum metallurgy solutions experiences a banner year

2020 was a strong year for Retech and the SECO/WARWICK vacuum metallurgy segment. Despite the ongoing global crisis, Retech as the leading supplier of vacuum induction melting (VIM), plasma (PAM), electron beam melting furnace (EB), and VAR furnaces, has completed...

READ MOREHART-TECH and SECO/WARWICK Join Forces to Develop Hardening Plant Solutions

For the past decade, SECO/WARWICK together with the HART-TECH hardening plant has been working together to engage in the evolving science of modern metal heat treatment solutions. SECO/WARWICK — one of the 5 largest global manufacturers of metal heat treatment...

READ MORESECO/WARWICK retort furnace solutions are ideal for tool manufacturers

SECO/WARWICK will deliver their unique technology to another tool manufacturer. The company will deliver a retort furnace with vacuum purging for oxidation. The retort furnace for the oxidation process operates under a nitrogen and hydrogen mix, then under steam, is...

READ MOREIn 2020, SECO/WARWICK vacuum technologies dominated the metal heat treatment

For the leading designer of the heat treatment solutions — SECO/WARWICK — the last year meant vacuum technologies. Despite unusual circumstances and uncertainty in the global markets, the SECO/WARWICK Group reinforced its position in the market as vacuum technology...

READ MOREStrong year (2020) for SECO/VACUUM

Aerospace and defense sectors lead the surge in new equipment orders for SECO/VACUUM (SVT), a SECO/WARWICK Group Company, with the tool and die market in a strong supporting role. In stark contrast to a generally cautious economy upset by a global pandemic, farsighted...

READ MORECorporate Social Responsibility according to SECO/WARWICK

2020 was a particularly challenging year. The Covid-19 pandemic has significantly affected many industries, companies and families. This difficult situation led to neglecting, forgetting or abandoning multiple social initiatives. Still, as one of the five largest...

READ MORE