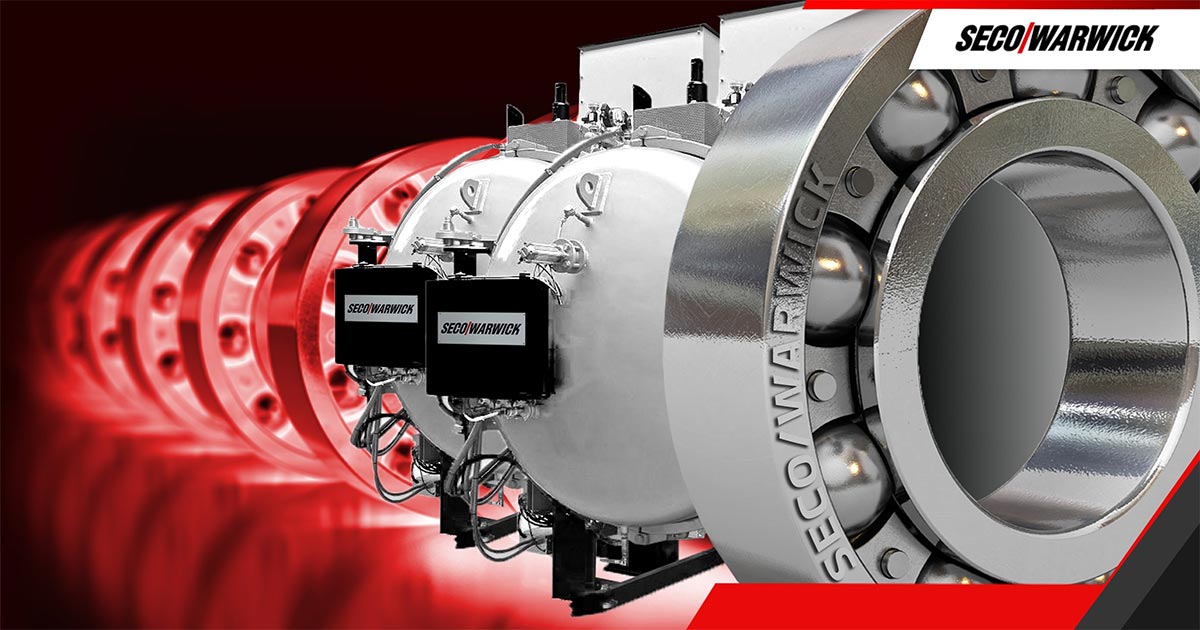

A SECO/WARWICK CaseMaster Evolution vacuum furnace and BREW atmosphere furnace will make up a new production line in the specialized commercial hardening plant of Aalberts Surface Technologies Heat in Kalisz (Poland).

Last year, the Dutch branch of Aalberts Surface Technologies Heat (formerly Hauck) in Eindhoven received a furnace, operating under high vacuum, with the working chamber of 1200x1200x2000 [mm], which is not only the largest furnace with an all-metal heating chamber but also the largest device of this kind to be operated in the Benelux Region of Europe (Belgium, the Netherlands and Luxembourg). Now the Polish, Kalisz-based branch of the heat treatment systems and services provider will expand its production line getting a solution that can only be described with “the most” prefix.

The new SECO/WARWICK furnaces will create a production line that will be used for successive vacuum carburizing (LPC) and gas quenching (CMe-T furnace), followed by annealing (BREW furnace) to reduce the internal stress of the treated metals. Performing so many processes is possible thanks to the combination of vacuum technology with atmosphere technology.

Performance and environmental-friendliness of the CMe-T

The three-chamber CaseMaster Evolution-T is a huge furnace with 1 ton per batch capacity and an annual output of up to 2,000 tons of parts. Such a device can successfully replace 3 conventional atmosphere furnaces. It is interesting to note that this furnace has an incredibly fast cool nitrogen chamber, achieving results similar to helium and oil cooling, creating an ultra-environmentally friendly system. Using the nitrogen taken from and discharged to the air eliminates both the use of expensive and difficult to obtain helium and harmful quenching oil. This makes it possible to reduce CO2 emissions by 300 tons annually. This is exactly the amount generated by three standard atmosphere furnaces.

“Aalberts Surface Technologies Heat had special requirements regarding the components and solutions used, and thus a T-series CaseMaster Evolution will replace the existing semi-continuous processes under protective atmosphere followed by oil quenching with complete vacuum heat treatment with low pressure carburizing and nitrogen quenching (25 bar!), delivering process precision and repeatability, and will probably be the quickest cooling furnace in the field with nitrogen quenching,” explained Maciej Korecki VP, Vacuum Business Segment at SECO/WARWICK.

On the other hand, the BREW 6810 solution will make it possible to perform the annealing process immediately after vacuum carburizing. It is a versatile furnace that can operate between 300 and 750 °C. It is equipped with a system enabling treatment under nitrogen atmosphere, preventing oxidation on the heat-treated workpieces.

CMe-T and BREW — a technological duet

The CMe-T furnace can replace the existing lines and atmosphere generators used for mass heat-treatment under protective atmosphere and oil quenching, whereas it ensures higher precision and process repeatability. The solution stands out, not only thanks to three chambers but mostly to the improvement of process quality results and cost reduction, twice the capacity and increased production flexibility with a compact design. The safety and environmental neutrality guaranteed by the CMe-T furnaces has become more and more important. These are among the key reasons for choosing a CMe-series furnace.

The BREW 6810 is a versatile furnace for annealing after vacuum carburizing. Its huge advantage is the turbo cooling — forced cooling system, making it possible to significantly shorten the annealing process. The combination of these two technologies, that is vacuum carburizing and annealing under a nitrogen protective atmosphere ensures a comprehensive solution where the heat treatment method required for both processes can be performed immediately one after another.

Successive projects

Both companies have been working together for many years now, increasing the production capacity of the individual branches of Aalberts Surface Technologies Heat. After Eindhoven, it was high time for the Polish branch of this global heat-treatment company to upgrade.

“According to our mission statement ‘Best-in-class’ is not about our core technologies but about our commitment to do everything we can to make our clients successful”, said Wojciech Matczak, Plant Manager at Aalberts Surface Technologies Heat Kalisz. “Our partner shares a similar mission, delivering to their customers reliable, safe and environmentally-friendly heat treatment solutions that ensure the economic efficiency of their business. Aalberts chose these solutions.

“Another solution delivered to a demanding customer, operating globally — in as many as 150 locations around the world — makes a great recommendation for the SECO/WARWICK Group, emphasizing our trustworthiness as a partner and testifying to the quality we achieved on the international market”, added Sławomir Woźniak, CEO SECO/WARWICK Group.

Growth requires a perfect partnership

SECO/WARWICK maintains continuous and close relationships with their customers, both at the management level and with the technical and maintenance personnel. Sharing information about processes, materials, shapes of workpieces, challengers and problems is a valuable source of research, changes, trials and subsequent iterations for the SECO/WARWICK technical laboratory. The knowledge from this customer, (Aalberts) and other commercial hardening plants is even more valuable since it comprises a wide range of materials and solutions that are hardened on the market.

Both companies have been cooperating for many years, both globally and in Poland. The two new solutions are not the first ones to be delivered to this Aalberts site. According to experts from both companies: “this cooperation has created a 3-in-1 alliance: partnership, trustworthiness and reliability”.