The Additive Manufacturing world requires a proactive approach from heat treatment furnace producers as 3D printing technology is evolving rapidly and furnace design needs to keep up.

Don’t let heat treatment equipment be ‘the weakest link’ in your production process.

Metal additive manufacturing (AM) – a top 10 trend

Metal additive manufacturing (AM), which, according to Gartner, is ‘the capability to create a physical object from a digitally encoded design through the deposition of material via a 3D printing process’, has become a top 10 strategic technology trend for manufacturing industries. The reason? It is much easier and faster to print necessary elements in-house than to wait till the end of the metal casting process. The 3D printing concept is about 30 years old, and Military and Aerospace sectors were among first industries interested in the potential of such a technology. Years have passed and yet, according to Grand View Research and their Trends Analysis Report, Military and Aerospace sectors along with Medical continue to be the most promising areas for Metal Additive Manufacturing technology development.

Over the last few years, the Automotive industry has joined that group due to a new direction of alternative fuel and weight reduction that are main goals for next generation vehicles. As Forbes claims, in 2019 , 51% of enterprises are using 3D printing in the production process, and 80% say that technology allows them to develop innovation faster. Data provided by Markets & Markets concerning this technology confirms that the global size of the 3D printing market is expected to reach about 35 USD billion by 2024, and, in comparison, in 2018 it was only 9.9 USD billion. Although perspectives are undoubtedly promising, it is logical to think there will be growing industry demands in other manufacturing applications to achieve the highest possible quality and durability, since metal parts printing is just a first step in an integrated production process.

Heat treatment steps into the spotlight

As 3D printing technology expands, production companies continue to look for technological capabilities to enhance printed product quality, especially due to the nature of sectors interested in the production of complex metal parts with superior mechanical properties. It hasn’t been until relatively recently that heat treatment processes have become quite such an important consideration in the 3D printing technology sector.

With regard to the production process’ performance, speed, and costs, more and more insightful data indicate the importance and potential impact of utilizing a heat treatment furnace in the additive manufacturing cycle, putting a brighter spotlight on the significance of heat treatment processes than ever before.

A few years ago, having one 3D metal printer was a great accomplishment. According to ‘Additive Post-Printing Survey’ released by Post Process, today more than 50% of 3D printer users have two or three different types of technologies at their disposal. 33% are using four or more printer types in their shops. Yet, apart from becoming affordable, the technology itself must produce quality products in both rapid prototyping and mass production. Accordingly, disadvantages of one technology need to be compensated by advantages of other one, and the furnaces, installed somewhere in between, must accommodate both.

A chain is only as strong as the weakest link

It could be said that 3D printing may enhance product development in literally every industry. Bearing in mind that a simple equipment is not enough to satisfy today’s 3D printing business needs and requirements, a question arises – what furnace will successfully face the challenge?

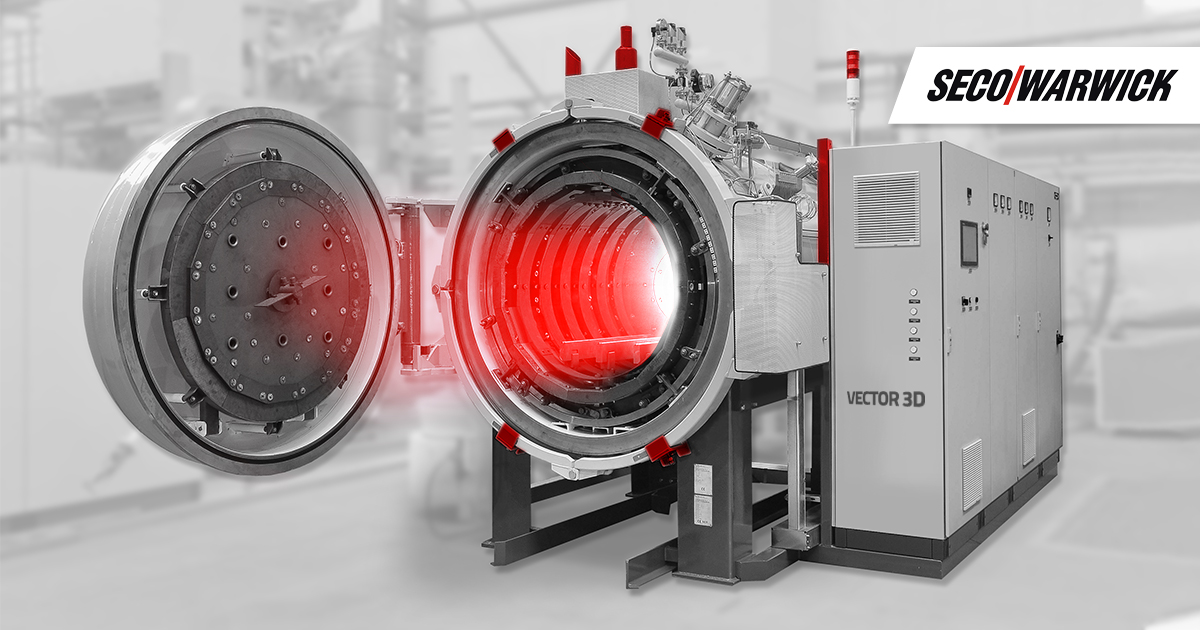

For instance SECO/WARWICK. The company is considered to be one of the heat treatment industry leaders, began introducing Metal Additive Manufacturing furnace solutions several years ago. As Sławomir Woźniak, SECO/WARWICK’s CEO says: “As a company, we are constantly searching for solutions that will align with our customers’ current and future needs, and the field of Metal Additive Manufacturing is no exception.”

Heat treatment stayed in the shadows of the 3D printing world for a long time; however, more and more users are beginning to realize the beneficial impact that proper heat treatment solutions contribute in terms of process time and costs. Both laser-based and binder jetting 3D printing technologies are characterized by features needed in the industry. Accordingly, the laser based solution is more common, but there is noticeable and growing industry interest in parts printed as a combination of powder and binder (green part). Nevertheless, the final effect is still far from a solid metal piece.

So where is the place for the furnace in either of these technologies?

Regardless if the manufacturer uses a high resolution laser-based printer or a fast, economical binder jetting solution, the heat treatment process will have an important impact on the performance of the final part. For example, the binder jetting sintering process uses a binder which needs to be removed. After debinding, the part is put into the furnace where the right sintering recipe makes all the magic. However, if the binder in the printed part comprises about 2%, debinding is no longer needed thanks to innovative solutions. Furnaces with the proper technology and recipes are capable of removing the binder, then starting the sintering process immediately afterward. In the case of laser printed parts, heat treatment furnaces are being used for stress relieving and annealing processes in order to achieve the best possible material homogeneity and quality.

Such solutions result in a solid metal part which is comparable to a cased one.

Various needs. One challenge.

Taking into consideration the size of laboratory furnaces, they are perfect for small batches and R&D purposes, but for medium and high volume production industrial furnaces are required. S. Woźniak specifies: ”In certain areas printing takes less time than heat treatment itself, and this is the reason why the furnace size needs to be adjusted to match estimated production capacity. Eventually, to achieve final properties required by the end user, printed parts need to be further processed. Dealing with a green part is only a tip of the iceberg, especially considering the importance of current requirements regarding certifications and standardization of printed components. So, having the capability of performing numerous processes in house will become an increasingly valuable benefit.”

Aerospace, medical and automotive sectors are main targets for 3D printer producers and those sectors deal mainly with special types of steels and superalloys. Benefits of processing such materials in vacuum heat treatment furnaces are already well documented, including integrated process controls which directly influence the part’s deformation or shrinkage aspect. Regardless of the binder base technology, this is a great solution.

To be one step ahead

Currently, vacuum heat treatment furnaces seem to be the most comprehensive heat treatment solution for 3D printing needs, even as those needs may vary. For instance, one technology requires sintering, while another needs stress relieving. Thus, taking into consideration the manufacturer’s future goals – such as standardization of a furnace, mass production, or constant flow of orders – investment in the right industrial furnace allows companies to avoid most of the obstacles before they even occur.

In fact, companies are constantly searching for dedicated solutions for their particular needs, and this is the reason that more and more customers from the 3D metal printing world are turning to heat treatment solutions from SECO/WARWICK Group.