SECO/WARWICK, a global leader in CAB technologies, has signed a contract to deliver a controlled atmosphere brazing line for air-conditioning system components. The new line will be used to produce air-conditioning condensers and evaporators. This is the third order from this Chinese customer.

Air-conditioning system production without secrets

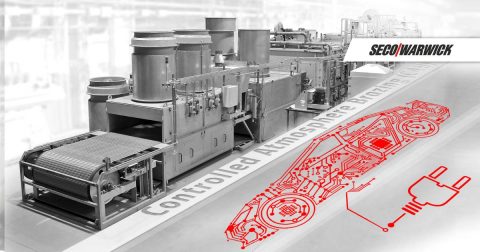

SECO/WARWICK delivered the first furnace to this partner more than 10 years ago. The new CAB line will help to maintain its crucial position in the automotive air-conditioning system market. Heat exchangers are manufactured using highly specialized continuous lines for controlled atmosphere brazing (CAB), and SECO/WARWICK is one of the world’s most recognized significant manufacturers.

“We have observed growth in the demand for CAB lines in the segment of heat exchanger production. We sell more and more of them. Our equipment is operated on five continents. The continuous CAB furnaces use a variable speed drive and a stainless-steel mesh belt to move products. The controlled atmosphere brazing (CAB) process heats a product to brazing temperature while maintaining a uniform temperature within the product in an oxygen-free nitrogen protective atmosphere

In 2021, we sold several CAB lines in China alone. A few of them are solutions used to manufacture battery coolers for electric and hybrid-electric vehicles. The growth of the electromobility segment, legal regulations, and the increasing awareness of the global society associated with the need to care for the natural environment, gives SECO/WARWICK high hopes for the product line dedicated to the battery cooler segment,” said Piotr Skarbiński, Vice-President, Business Segment Aluminum Process and CAB, SECO/WARWICK.

Condensers and evaporators — critical components of air-conditioning systems

A condenser, also known as an air-conditioning cooler, is a heat exchanger responsible for removing the heat from the refrigerant coming from the evaporator, which takes the heat from the cabin air. The condenser is usually installed at the front of the vehicle, just in front of the radiator. In turn, the evaporator is the component of the air-conditioning system, which takes the heat from the air coming from the vehicle cabin. Air dehumidification is another essential feature of the evaporator. Both components are crucial for the correct operation of the vehicle air-conditioning system. They are manufactured using highly specialized aluminum brazing lines.

The advantage of the line on order consists of the powerful gas heating method, which ensures significant energy savings thanks to heat recovery. The CAB line guarantees efficiency, reliability, and repeatability of the process every time.

The automotive partner joins the SECO/WARWICK team yet again

This order, which will be delivered in June, is another case of the cooperation between both companies. The high position of SECO/WARWICK in the CAB segment results from perfect collaboration with the customers, both in terms of sales and after-sales support. SECO/WARWICK is renowned for its quick, efficient (local) equipment service and reliable work.

“We have a great reputation on the Chinese market. We deliver CAB lines to many leading manufacturers of heat exchangers. Our partners are attracted to the powerful and efficient gas heating method and the reliability of SECO/WARWICK equipment, along with our professional after-sales service,” highlighted Liu Yedong, Managing Director, SECO/WARWICK in China.