CAB technology leader SECO/WARWICK, will modify the equipment in operation at an Asian customer serving the automotive sector. This is a continuation of a 2018 project, which involved the delivery and commissioning of a controlled atmosphere brazing line.

The planned expansion includes an extension of a radiation-heated brazing furnace, an additional zone of the cooling chamber with an air jacket, additional zones of the final cooling chamber and a modification of the control system. SECO/WARWICK will carry out the entire modification and take care of the correct configuration and commissioning of the equipment.

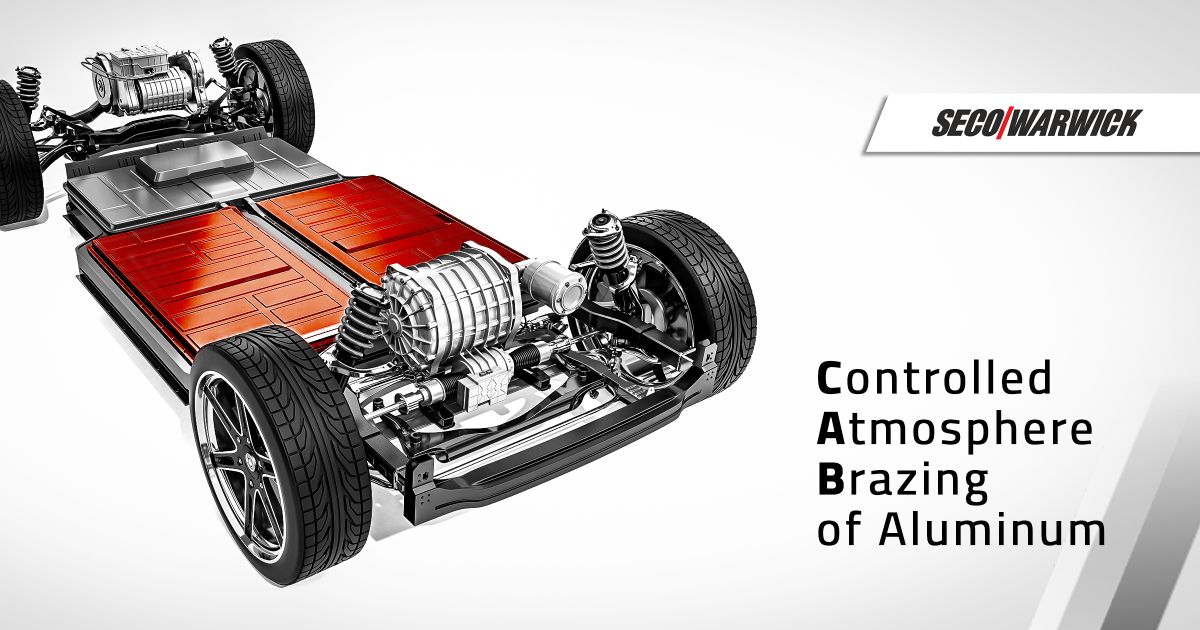

The expansion of the CAB line comes as a result of an increase in orders to produce battery coolers for electric vehicles that the Chinese plant has received from the automotive sector. After two years of intensive operation, the existing line has to undergo a major expansion to increase its production capacity.

“This is not our first project for this manufacturer. Back in 2010, we modified an AFC CAB line which was transferred to China from abroad. It was one of our first large-scale modernisation projects and it was a success. The furnace, which is now 11 years old, is still operational and performing perfectly,” says Piotr Skarbiński, Vice-President of Aluminum & CAB Products Segment, SECO/WARWICK. “Just three years later, we had an opportunity to work together once again. We sold a brand-new CAB line at that time, and now three years later we upgraded it so that the plant could continue to grow,” recalls P. Skarbiński.

The automotive industry and SECO/WARWICK

However, this was not the end of a successful collaboration between the two companies. In 2018, the customer purchased another CAB line, and two years later SECO/WARWICK received an order for modernisation that was intended to once again increase the customer’s production capacity. The production of battery coolers for electric cars is growing at a staggering rate, along with the growing demand for electric and hybrid vehicles worldwide. This has to do not only with the development of this technology, but also with the recently introduced restrictions on emissions.

SECO/WARWICK, one of the innovators in the field of CAB brazing technology, is working closely with the automotive industry to provide solutions that help to further develop the technology for manufacturing electric vehicles.

“The recognition of the SECO/WARWICK Group in the CAB sector is very high. Our customers have chosen SECO/WARWICK because of its reputation as a leader in CAB technology with a focus on R&D. The second aspect that is often emphasised is dialogue, in other words, seeking new, innovative solutions together with our partners,” concludes Sławomir Woźniak, CEO of the SECO/WARWICK Group.

The key to the success of SECO/WARWICK’s CAB line is the perfect temperature uniformity across the entire belt width. The system offers an additional innovation in the form of a unique design of the curtain sections and cooling chambers and special design to prevent deformation of long battery coolers. The entire project is the result of the collaboration between SECO/WARWICK and the largest global automotive industry organizations.