Imagine being able to test the functionality of an industrial furnace at the design stage, without having to build a physical prototype. Or verifying the pumping system’s efficiency before it is installed in the production hall. And what about simulating the furnace’s heating rate depending on the power source – all this without touching the actual equipment?

This is what the Digital Twin of an Industrial Furnace gives you

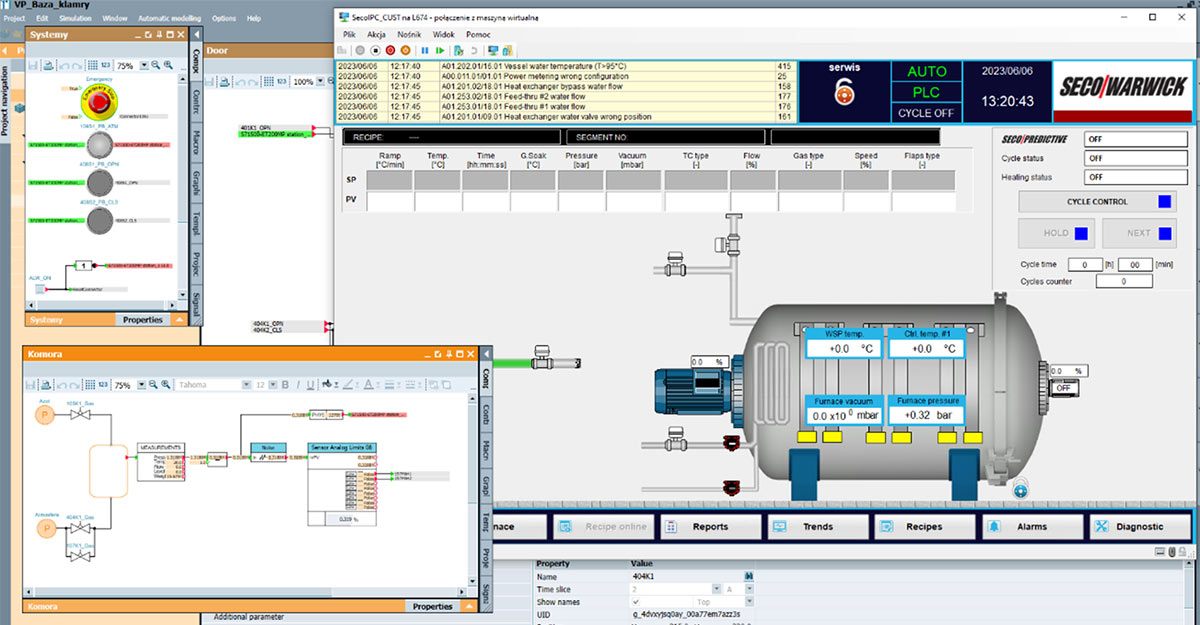

Thanks to the use of the industrial furnace’s Digital Twin, you can test both the software (e.g. PLC, SCADA) and the functionality of the control cabinet at the design stage or in the production hall, or directly, during commissioning, at the installation site. It is also possible to test the furnace functionality and the “virtual” technology by the Service Team, even before the physical unit is ready.

If you want to know how a Digital Twin can help optimize your projects, or you have a real need to execute, please contact us. The Digital Twin is not only a modern approach, but a real tool that changes the rules of the game by allowing users to engineer both the equipment and the process in real time.

This is just one of many ways that we innovate the art and science heat treatment at #SECOWARWICK.