Ponar Wadowice S.A., a part of Ponar Silesia, signed a contract for the May 2016 delivery of a SECO/WARWICK CaseMaster Evolution (CME) low pressure carburizing (LPC) furnace, the first such furnace purchased by Ponar Wadowice.

This modern, reliable furnace is a standard design for SECO/WARWICK, proven in a wide range of LPC applications, and able to address many technical challenges in LPC including oil hardening.

PONAR Wadowice S.A. is an expert in designing and producing complete solutions for the power hydraulics industry. The products are widely used in mining, metallurgy, energy, mechanical, chemical and military.

“We are moving to a new stage of development in PONAR Wadowice and we are happy to implement this state of the art technology that offers a new quality as far as reliability, continuity of service, efficiency and quality of the final product is concerned”, says Rafal Worek Operation Director of PONAR Wadowice.

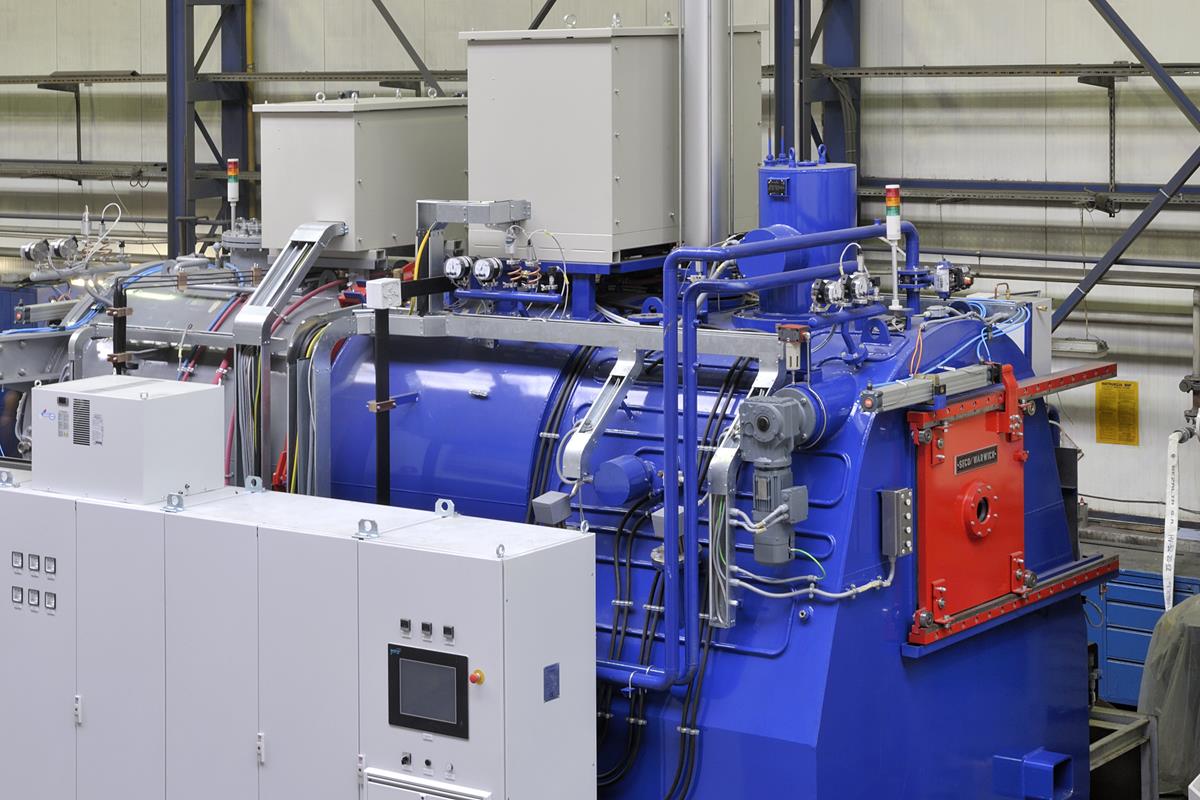

The new CaseMaster Evolution is a double chamber vacuum furnace with oil quenching system. It prevents intergranular oxidation through the process of low pressure carburizing in a vacuum furnace. It’s equipped with FineCarb® – low pressure carburizing technology and PreNitLPC® – a technology of intensive vacuum carburizing.

It is going to deliver much higher quality final products than atmospheric furnaces and decrease operating cost. There are a number of benefits in using this new SECO/WARWICK furnace. It’s up to 40% more cost efficient, it’s safer for the environment, safer for workers, and provides an increase in production volume of 15%.

“We are very happy to provide this sophisticated solution to a company from Poland where the roots of SECO/WARWICK are. I believe that our technology will slowly change the competitiveness of Polish companies in the global market and locally improve environment and worker safety”, adds Paweł Wyrzykowski, President & CEO SECO/WARWICK GROUP.

More about CaseMaster Evolution furnaces

There are a number of applicable technologies for this type of furnaces:

- High-temperature carburizing by PreNitLPC®,

- Low pressure carburizing by FineCarb ,®

- Bright hardening,

- Oxidation in the preheating chamber,

- Annealing,

- Tempering.

CaseMaster Evolution is a new economic generation of sealed quench furnaces used in various industries – aviation, automotive, machine-building, bearing and commercial heat treatment.

Main Advantages of CaseMaster Evolution furnaces:

- Uniformity and high quality of parts following heat treatment,

- High temperature carburizing for the typical & special steels,

- High-speed & economic process performance,

- Very low consumption of processing mediums,

- Nominal temperature up to 1320oC Oil or Gas quench features,

- Reduction of distortion and their repeatability,

- Process simulators & fully automated processing,

- Flexibility, no furnace idling periods, quick start up & shut down,

- Very short workload transport time within the furnace, fast opening & closing of internal door,

- Compact and modular design,

- New design of an oil circulation system enabling maximum uniformity and rate of cooling.

The furnace meets AMS2750D, AMS 2759, BAC 5621, PN-EN 98/37, PN-EN 746-1.

More info about the furnace and technologies:

https://www.secowarwick.com/en/products/vacuum-carburizing/

https://www.secowarwick.com/wp-content/uploads/assets/Documents/Brochures/PreNitLPC-EN.pdf