One of the largest Brazilian hardening plants has started to operate a SECO/WARWICK Vector® vacuum furnace — one of the flagship products of the Group. The vacuum furnace is equipped with 15 bar abs. high-pressure gas quenching, cryogenic hardening and tempering has been in operation in South America for several months.

Thanks to the unique solutions available on the market, that is directional cooling in a cylindrical chamber, cryogenic hardening and isothermal cooling, the hardening plant will be able to expand their customer portfolio with the demanding aviation industry. The device was assembled and commissioned by SECO/WARWICK in cooperation with their South-American partner — Combustol.

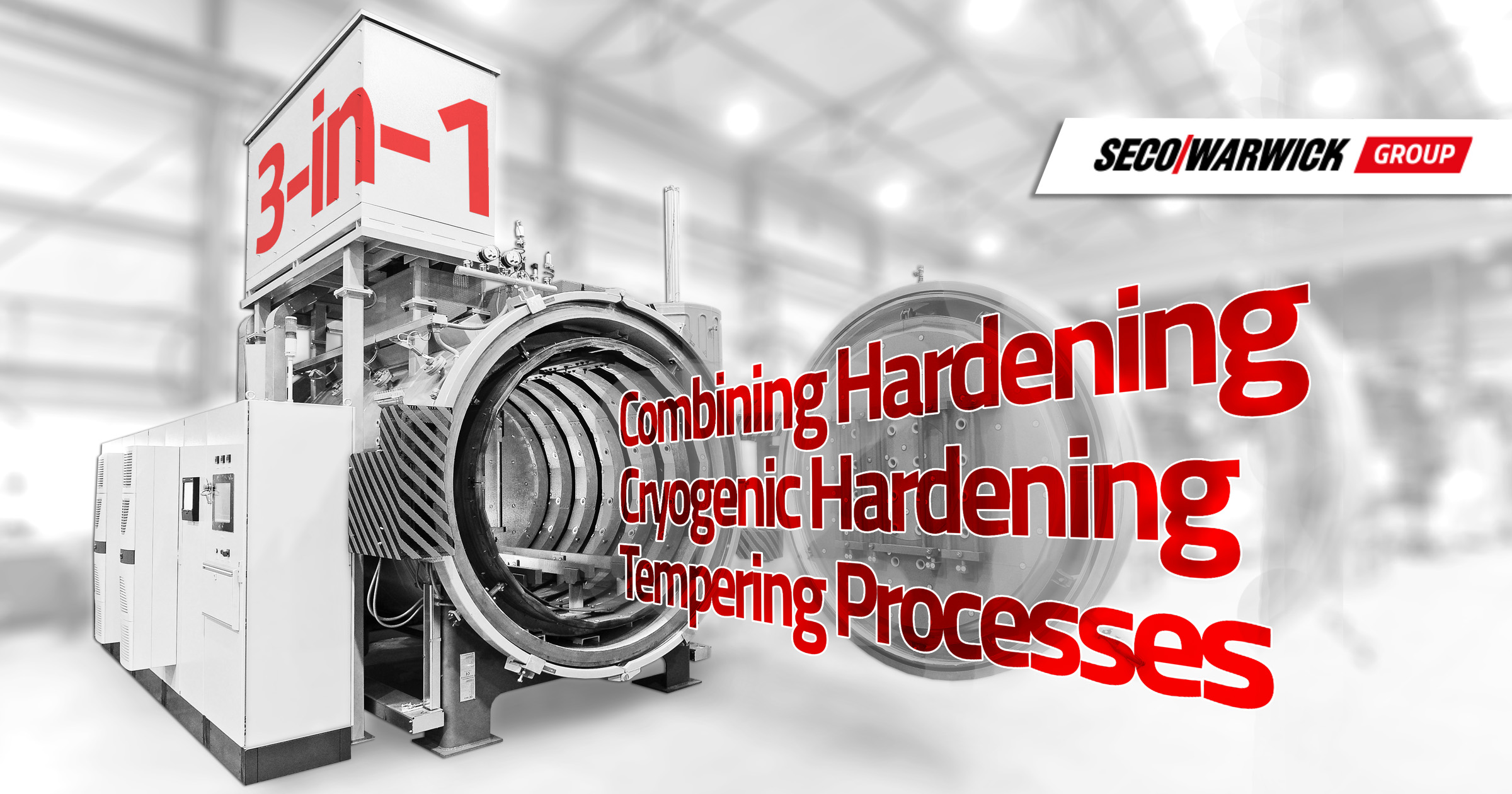

3-in-1 — one vacuum furnace, three processes

The installed furnace is a “3-in-1” solution — one device instead of three, combining hardening, cryogenic hardening and tempering processes. The Vector vacuum furnace enables performance of the three processes, significantly increasing the hardening plant’s capabilities. The isothermal cooling process increases the metallurgical properties of the large dies processed and extends their useful life, whereas the cryogenic hardening makes it possible to complete the austenitization process, and improve the properties of the workpieces. This particular design is distinguished by directional cooling in a cylindrical chamber, which enables optimum cooling of items with complex dimensions. This option optimizes system performance and reduces the distortion generated during gas cooling. The device also features an above-standard working space (900x900x1200) that enables efficient heat treatment of large items, which also translates into a significant increase in the output of the hardening plant.

“Using a single furnace with optional equipment for three heat treatment processes — hardening, cryogenic hardening and tempering — provides hardening plants with invaluable benefits. The device is simpler and quicker to install than 3 separate furnaces. It also requires less installation space, provides important energy savings — up to 40%, and shortens the individual cooling times with shorter treatment and cooling times” — said Maciej Korecki, VP, Vacuum Business Segment at SECO/WARWICK. “The Vector is our flagship product that continuously receives interest from various hardening plants around the world, and the fact that we have had the opportunity to commission it at one of the largest commercial hardening plants in Brazil is even more exciting. This is another customer from this sector that appreciated our global product recommendations, the uniqueness of our solutions and their customizability” — M. Korecki added.

The Versatile Vector is ideally suited for the industry requirements for commercial hardening metal heat treatment

Commercial hardening plants are enterprises that have a very rare knowledge of metal treatment. Everyday, commercial hardening plants face the problem of many types of materials, with a vast range of processes and methods. This is one of the most experienced groups when it comes to vacuum heat treatment. SECO/WARWICK delivers the solutions that will work perfectly in this demanding environment thanks to its unique capabilities. The delivered furnace offers huge diversity both in terms of workpieces and available technologies. The Vector family of furnaces with auxiliary equipment are as versatile as the commercial hardening plants operating on the metal processing market.

“We were chosen because we are the only company to deliver a device that offers directional cooling in a cylindrical chamber, cryogenic hardening and isothermal cooling in one piece of equipment. The device is also equipped with a dew point sensor — a system to solve one of the very critical aspects of heat treatment, which prevents the oxidation of parts during cooling by means of controlling the gas quality. With these many features, our clients are able to complete orders for the aviation industry, which have to comply with numerous quality standards such as AMS2750F” — commented M. Korecki.