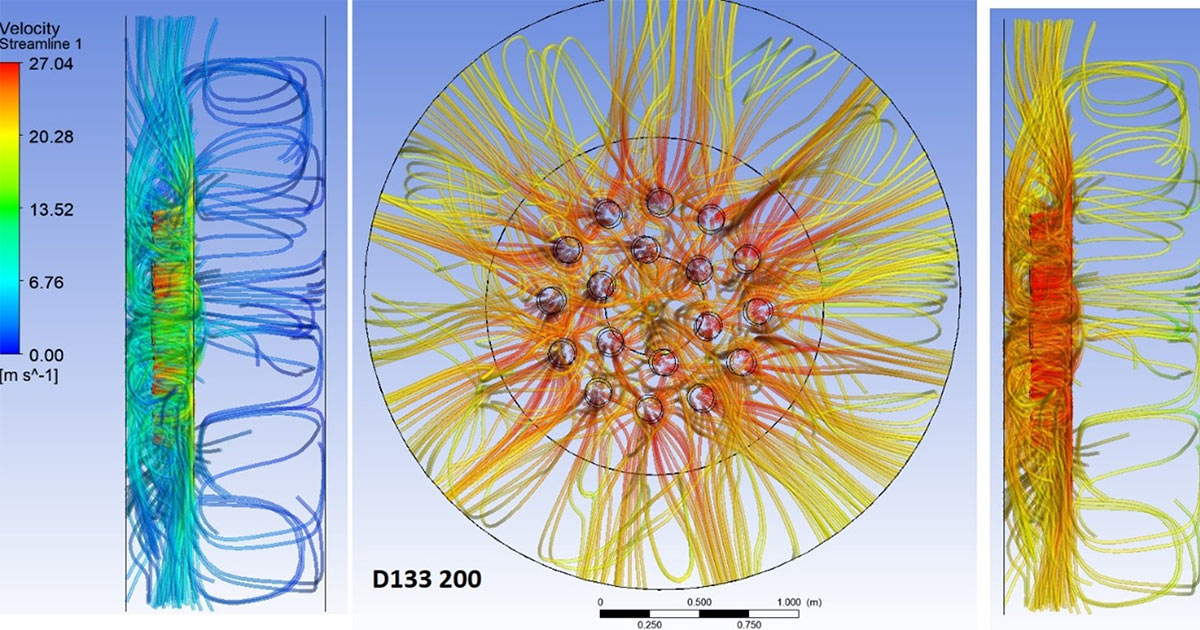

Continuing with the topic of blowing systems’ optimization, it is worth taking a look at how Ansys Fluent can be used to automate processes in the modern Vortex 2.0 solution. This advanced tool offers many possibilities which can significantly increase efficiency and reduce aluminum coils’ heating time.

1 Gas flow for Vortex 2.0

1. Automatic Parametric Optimizations

Vortex 2.0, integrated with Ansys Fluent, enables automatic parametric optimizations. Engineers can define parameters’ ranges such as air velocity, temperature or channel geometry. Ansys Fluent automatically runs simulations for these parameters’ different combinations, identifying the most efficient settings. This allows to quickly find optimal solutions without having to manually test each configuration.

2. Scripts and Macros

Ansys Fluent supports the scripts and macros creation which can automate repetitive tasks in Vortex 2.0. Engineers can write Python scripts to automate simulation, analysis, and optimization processes. For example, you can create a script which automatically runs simulations for different geometries and saves the results for analysis. This significantly speeds up the optimization process and reduces the human error risk.

3. Integration with Data Management Systems

Vortex 2.0 can be integrated with data management systems (PDM/PLM), allowing for simulation results’ automatic storage and management. This allows engineers to easily access historical data, allowing for better trends understanding and faster decision-making. Data management automation also eliminates the need for manual data entry, which saves time and minimizes the error risk.

4. Topological Optimization

Ansys Fluent can be integrated with topological optimization tools which automatically generate optimal shapes and structures in Vortex 2.0. This process involves iteratively modifying the geometry to find the most efficient solution. Automating this process allows for new designs’ rapid creation and testing, which accelerates the innovative solutions’ development.

5. Machine Learning and Artificial Intelligence

The use of machine learning (ML) and artificial intelligence (AI) in Ansys Fluent opens up new automation possibilities in Vortex 2.0. ML algorithms can analyze simulation results and predict the most efficient configurations based on previous data. AI can also automatically adjust simulation parameters in real time to optimize heating processes.

Summary

Optimization automation with Ansys Fluent in Vortex 2.0 is a powerful tool which allows for significant increases in the blower systems’ efficiency. With automatic parametric optimizations, scripts, integration with data management systems, topological optimization, and the use of machine learning and AI, engineers can quickly and efficiently optimize heating processes. All this translates into savings of time, energy and costs, making Ansys Fluent an indispensable tool in the aluminum industry.