The pandemic situation and the related need to ensure maximum compliance with the supplier-customer agreement by verifying the existing procedures and system performance has forced the use of new methods of operation. When travel is severely restricted and engineers work from home, remote acceptance testing of furnaces becomes a must.

To meet this situation, SECO/WARWICK and Retech have recently implemented a comprehensive FAT (Factory Acceptance Test) remote program. The clients who have already taken advantage of these opportunities are companies from China, Mexico and South Korea.

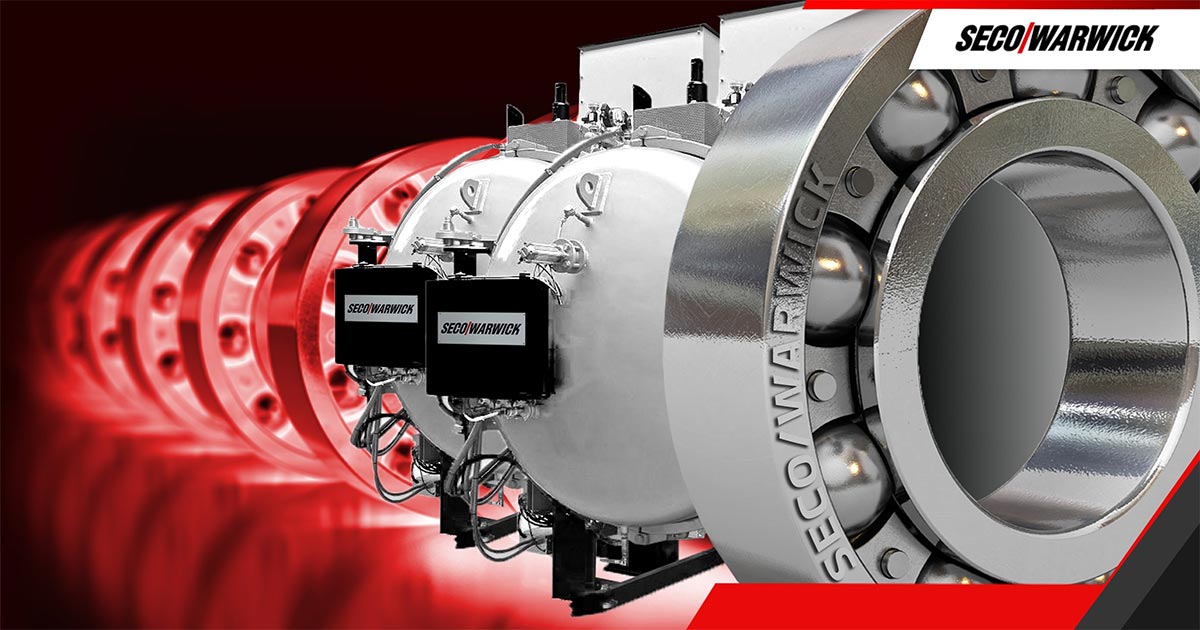

The systems tested under the new program were furnaces for vacuum metallurgy using VIM technology (vacuum induction melting). In accordance with the SECO/WARWICK Group standard, this type of equipment is normally verified in the presence of the customer in the field by performing cold and hot tests.

“We are ready to carry out comprehensive tests of our furnaces prior to shipment. The technical infrastructure at hand enables the performance of hot tests covering most metals used in industry. The exception is titanium, which is a metal that reacts strongly with water and has special safety procedures, including the use of a technological bunker. We verify in practice all the operating parameters of the furnace and the associated peripheral devices, such as loading systems or closed cooling circuits, in full production cycles,” confirms Jacek Trzpil, Deputy Director of Operations Vacuum Melting at SECO/WARWICK.

Is the comprehensive FAT remote acceptance program a new standard for the metal heat treatment and metallurgy market? Time will tell.

The SECO/WARWICK Group has applied the experience, knowledge and solutions successfully used for several years in the field of monitoring and remote operation of its systems in real time mode. These technologies are widely known and used in various configurations, but it was rare, however, to engage them at the commissioning stage with the customer. The state of emergency in which production plants all over the world find themselves has forced the industry to ask these questions and to adapt them both on the part of the producer and the recipient. We need to be aware that the industrial vacuum metallurgy furnace is a technically advanced, complex device that is assessed through the prism of many aspects: technical, technological, safety, ergonomics, etc. In addition, there are industry and/or factory standards.

The first four tests for two Chinese customers and one each from Mexico and South Korea were carried out completely remotely with no customer engineers involved. Recordings from individual cameras, sensors and viewfinders were downloaded to secured servers and made available to customers. The tests were successful, and the adopted procedures guarantee the reliability and completeness of the data. In this respect, these methods can be successfully used for other customers.

Technological tests

“Remote acceptance testing is a highly requested service today. I could say that the financial rationale for such action has always existed, while the epidemiological threat has been the catalyst for change. It is a win-win action. Time-consuming and costly journeys can be avoided by maintaining a comprehensive testing procedure, supplementing reports with videos of activities and process flow, and the ability to analyze data online. For the first time, we did not send a team of engineers and technicians from the USA to Poland for testing. This is a huge time savings for specialists who could stay in their locations and successfully analyze test runs from remote offices or home,” says Robert Szadkowski, VP Aftermarket at the SECO/WARWICK Group.

“Currently, there is no problem with setting up a fast, encrypted link, after which the customer, service technician or external auditor can fully participate in the research. This can be done in many different ways. We are supported in this by the IoT trend, and in our systems, the standard of equipment and network communication at the PLC and HMI & SCADA level. Rather, the bigger problem was the mental change of the process participants, who had to deviate from the usual patterns and procedures. Has it affected the quality of the reception? In no case. I think in a few years we will wonder why we didn’t do it before, when it was technically possible,” adds Szadkowski.

“Innovation is inscribed in the DNA of the SECO/WARWICK group, regardless of the area of operation. Customer service support, equipment and system diagnostics are pieces of a larger puzzle. The ultimate goal is the smooth, trouble-free operation of the equipment. At Retech, we create new technologies of vacuum metallurgy, and at the same time we adapt the innovations of other fields, including communication, both human and with devices, mobile access, control and diagnostics. SECO/WARWICK has great achievements in these areas. Remote commissioning of furnaces is the materialization of development activities,” concludes Earl Good, Managing Director of Retech, a subsidiary of the SECO/WARWICK Group.

We asked Robert Szadkowski, VP Aftersales, about technological progress in device acceptance and remote tests:

Are we ready for online testing?

We would first need to define what exactly we mean by remote testing. It should be taken into account that almost every furnace for heat treatment or vacuum metallurgy is a device designed and built from scratch and tailored to the specific needs of the customer. For this reason, the first testing in the hall, which is an integral part of the production process, verifying the correct assembly of mechanical parts and electrical installation should not be transferred to the scope of remote work. There is no logistical justification for such an idea. However, acceptance tests, and FAT in particular, yes. As long as we have knowledge and proven solutions in the field of data registration, sharing and reporting, it is a very practical option. Real-time tests consist of sharing streaming, online transmission from multiple cameras and sensors at once, and then supplementing the material with formal reports in accordance with the requirements of the standards and the contract itself.

Is it possible to commission a furnace at the customer’s site without SECO/WARWICK engineers?

Yes, that is also possible. We do not have such experience yet, but in my opinion, it would be of great benefit to both parties. Let’s remember that the delivery of a new furnace is a complex process in which the supplier and the recipient play important roles together, and success is the result of their cooperation. It starts at the stage of making arrangements regarding the expected technical and technological parameters, continues throughout the production and commissioning period, and then during the warranty and post-warranty period. The participation of the customer, the end user of the furnace, in the acceptance tests is required, as is training of the operating personnel. So why could the commissioning of the furnace not be carried out by a customer with SECO/WARWICK remote support? There are exceptions to this when dealing with high-risk systems, but for many systems this would be perfectly acceptable. Again, I must conclude that this will be primarily a challenge to our ideas and internal acceptance, rather than to technical limitations.

Is Remote Testing an “Invention” because of the current travel restrictions?

As I mentioned earlier, such solutions existed and were ready for use at least a dozen years ago. The pandemic, on the other hand, caused a wave of inquiries from customers about the possibility of conducting such tests remotely, which resulted in the transition to their implementation. From a purely technical point of view, we at SECO/WARWICK have been successfully using these technologies for internal device supervision for at least 10 years. Remote access, and currently real-time data analytics in terms of predictive maintenance, is an area where we are constantly developing modern tools. In our work, we use remote supervision tools and applications, we report OEE indicators, and we conduct optimization processes in terms of batch queuing or energy factor consumption. We are also working on solutions in the field of service support and the use of SECO/LENS augmented reality. It is true that Covid 19 changed the rules of the game, but in this particular case, to the benefit of the industry.