Retech, a division of SECO/WARWICK Group, will be shipping a Rotating Electrode Gas Atomizer (REGA) to an overseas partner specializing in the production of refractory metals and alloys. This REGA is capable of producing powders suitable for a range of powder metallurgy processes.

“This is the first furnace Retech has sold to this company. They’ll have one of the workhorses of our Powder Production lineup. They can expect many years of reliable service for whatever powder applications they choose”

— Earl Good, Retech Managing Director.

One of the earliest metal powder production methods to be developed, REGA has the versatility to handle a wide variety of metals, including reactive-, refractory-, and super-alloys. As a first-choice supplier of several powder metal production systems, Retech continually innovates new technologies and proves them out in its in-house R&D facility.

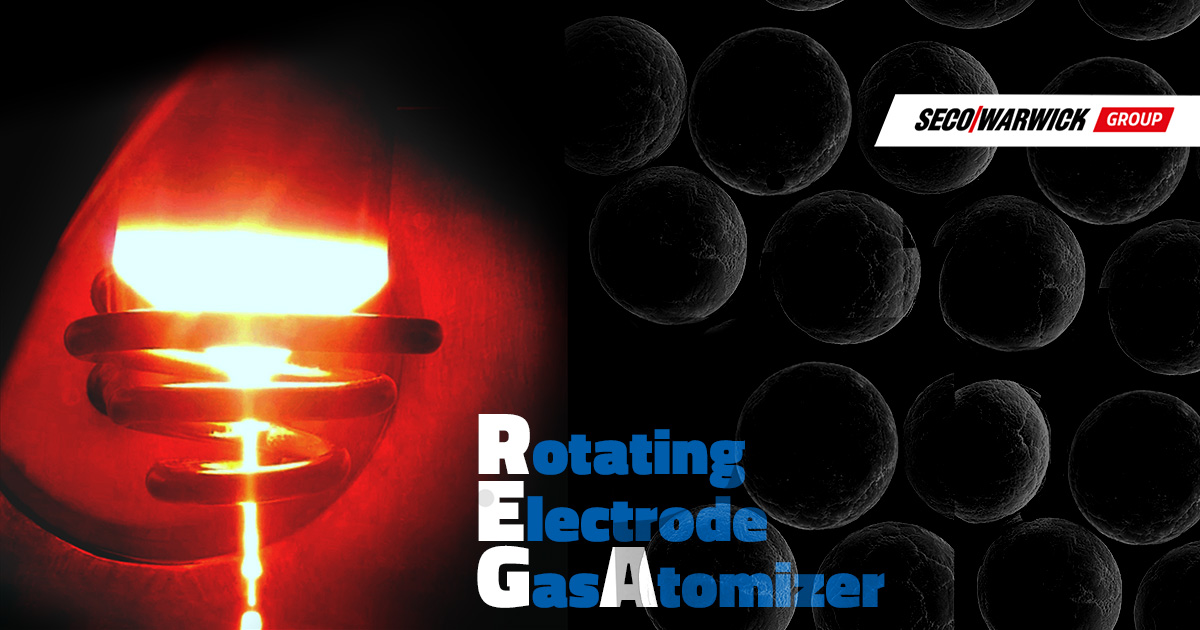

REGA Principle of Operation

REGA technology produces powders by melting a vertical electrode, rotated as it lowers to ensure it melts evenly. The stream of melted metal falls into a high-pressure jet of inert gas which disperses the stream into droplets, cooling and solidifying them before they strike the chamber walls. The size and uniformity of the powder sphericules can be selected for by adjusting the melt rate and the pressure and angle of the jet of gas.

Among the first furnace types to be assembled at Retech’s new Buffalo plant, this is a fitting accomplishment on the eve of the company’s 60th anniversary.

This REGA furnace will enable the customer to meet regional demand more easily and to diversify their offerings.