Isoflama is expanding its hardening plant and has ordered a new and modern Vector® vacuum furnace, which will be connected to the superior production system, significantly streamlining the cycle and improving the Brazilian Partner's logistics.

Vacuum furnaces for dies for the automotive industry

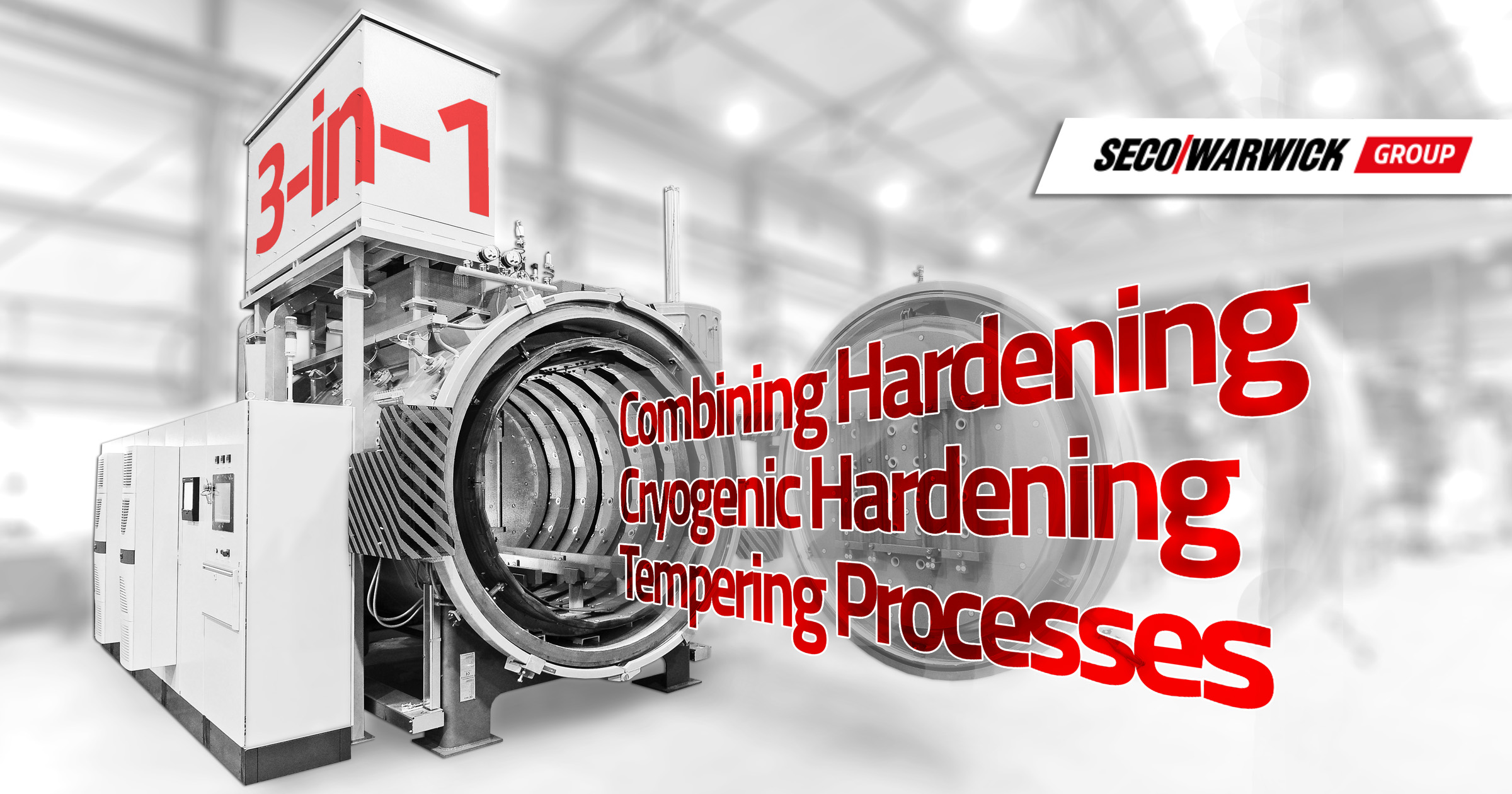

The furnace on order by the commercial heat treater – Isoflama solves the customer’s problem with implementing the plan to introduce an innovative heat treatment strategy to process large dies for the automotive industry presses hardening processes in its production. The Vector vacuum furnace is equipped with an efficient cooling system and a large working zone with increased load support beam capacity. This construction is enable Isoflama to carry out processes on very large and heavy dies.

“Isoflama is a special Partner, because they were the first customer from the Brazilian market to trust SECO/WARWICK. Today, they have several of our solutions in production, and a new one has just been ordered. The customer wanted to shorten the heat treatment cycle time. We have used a number of modifications in this furnace, which are a response to the commercial heat-treating plant’s specific needs. By expanding their machinery park, Isoflama will be able to shorten the heat treatment waiting times for its current and future customers,” commented Maciej Korecki, Vice President of the Vacuum Segment at SECO/WARWICK Group.

“Tailor-made” furnaces only from SECO/WARWICK

SECO/WARWICK is one of the leaders in the metal heat treatment vacuum furnaces market. Thanks to its flagship solution – the Vector furnace, which is used in 70 countries around the world, SECO/WARWICK is considered a specialist in this market segment. The furnace design has been improved over the years, making it perfect in every aspect, even in the smallest detail. The multitude of options with which this furnace can be equipped, makes it a versatile furnace working perfectly in commercial heat-treating plants using a number of processes. The Vector furnace’s well-thought-out design allows users to add and modify options at the production stage, creating a solution fitting perfectly into the Partners’ needs.

“This time too, we have created a unique furnace based on a standard solution. We have reinforced the support beam under the hearth to increase the process load rating by more than 60%. This was a key modification which will allow this Brazilian commercial heat treater to process heavy and large dies for the automotive industry. The furnace will also be prepared for later connection to a diffusion pump. Thanks to this, in the future, when such a need arises, Isoflama will be able to easily connect a high vacuum system to the furnace. Thanks to the installation of an inverter covering the blower’s full power, the Partner will be able to better control the hardening processes,” explains Łukasz Chwiałkowski, Sales Manager for this project.

The aim of personalization was to achieve an effective solution for the heat treatment of dedicated parts, as specified in the investment project – the hardening of very large dies for large presses used in the automotive industry.

Brazil – an important player in vacuum heat treatment

SECO/WARWICK has been operating on the Brazilian market for many years. The largest commercial heat-treating plants in this country operates on SECO/WARWICK solutions. In Brazil, commercial heat treaters are particularly keen to equip their plants with single-chamber Vector vacuum furnaces.

“Our development is dynamic, but at the same time well-thought-out. Expanding the machinery park in commercial heat-treating plants is a difficult topic. You should always consider various options, needs and adapt the purchase to a specific investment project. In SECO/WARWICK, I appreciate the fact that they have specialists who can not only respond to these needs, but also predict various options and propose the most effective and future-proof solutions. This is another purchase of SECO/WARWICK in a dozen or so years and I don’t think we will stop there,” said Thomas H. Heiliger from Isoflama Industria Comercio Equipamentos LTDA.

Isoflama has been operating on the Brazilian market since 2006. The first furnace to operate in the modern hall was a vacuum solution with a maximum cooling pressure of 12 bar from SECO/WARWICK. Over the course of ten years, Isoflama has expanded, acquiring new solutions for metal heat treatment. Today, Isoflama has a large machine park which makes it one of the most efficient and versatile commercial heat treaters in Brazil.