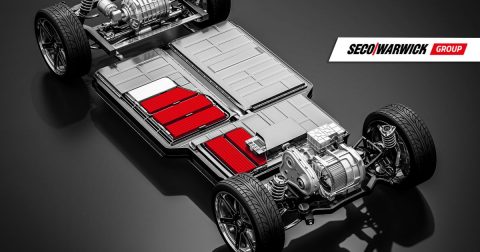

The latest brazing system from SECO/WARWICK will be used for large size battery coolers for cars. Car batteries, thanks to the development of electromobility, are the fastest growing product in the automotive industry. One of the world’s leading aluminum heat exchanger manufacturers has placed its trust in SECO/WARWICK for the seventh time.

The SECO/WARWICK controlled atmosphere brazing (CAB) line will consist of a convection preheating chamber, a radiation furnace, an indirect cooling chamber and a final cooling chamber. The entire system will be equipped with a dedicated control system. Ordering the fourth CAB line with the same configuration means that the customer is assured that the delivered equipment performs efficiently and reliably.

“Our current portfolio is the result of collaboration, dialogue and listening to the needs of our customers, mainly in the automotive sector. We have developed CAB lines that perfectly match market needs,” says Piotr Skarbiński, Vice-President, Business Segment Aluminum Process and CAB, SECO/WARWICK. “Our specialised CAB (Controlled Atmosphere Brazing) lines for the HVAC industry-heating, ventilation and air conditioning, and for the production of exchangers for the energy industry, allow us to significantly reduce CO2 emissions, and this is currently an invaluable asset,” adds P. Skarbiński.

CAB technology preferred

Controlled Atmosphere Brazing (CAB) is the preferred technology for the production of aluminum heat exchangers in the automotive industry. SECO/WARWICK has sold a similar machine to one of Europe’s largest automotive spare parts manufacturers. A dedicated line was tailored to the specific requirements of the battery cooler manufacturer.

SECO/WARWICK in China

The Asian history of SECO/WARWICK technology in this area began in 2010 precisely with aluminum brazing furnaces in a controlled atmosphere, where the Chinese SECO/WARWICK subsidiary became the undisputed market leader. The first CAB line produced by the Tianjin plant was installed and commissioned 10 years ago.

Compared with 100 years of the Group’s history, the establishment of a Chinese subsidiary is a relatively recent event. At the beginning of their 10-year history in China, the group started out with just a few people, then quickly grew to their current position today with 20 times greater sales revenue and more than 70 employees. SECO/WARWICK has delivered hundreds of implemented solutions manufactured in their 5000 m² facility that houses the head office and production area. The company serves customers in the most demanding industries – automotive, energy, aviation and machinery.

The new CAB line was designed by SECO/WARWICK based on our extensive experience in the design and manufacture of equipment for brazing battery coolers. A machine was needed to manufacture oversized battery coolers. The most important factor was developing the right design to achieve perfect temperature uniformity on the 1.9 m wide conveyor belt, including a special design to prevent the deformation of such long battery coolers. This is the key to a perfectly functioning production line. An interesting element in this dedicated solution is the unique design of the curtain box and cooling chambers.

For several decades, SECO/WARWICK has played an important role in the development and innovation of CAB systems, providing its customers with installations of the highest value and professional service.