CAB Furnaces (SYSTEMS)

Controlled Atmosphere Brazing (CAB) Furnaces for Aluminum

SECO/WARWICK is one of the world’s most experienced and innovative brazing furnace manufacturers with over 300 controlled atmosphere brazing (CAB) systems installed worldwide. Our commitment to quality products begins in our brazing center, application engineering and continues through the complete installation of your system, including aftermarket support.

CAB Furnaces

Controlled atmosphere brazing (CAB) of aluminum using a noncorrosive flux, is the preferred process for manufacturing aluminum heat exchangers. Since entering this field in 1984, SECO/WARWICK has led the development of advanced technology in the aluminum brazing process. Capitalizing on our many decades of furnace design experience, SECO/WARWICK has driven innovations such as:

/ Improved muffle design

/ Convection heating technology

/ High atmosphere quality solution

/ Vacuum purging system for semi-continuous and batch furnaces

/ ACCUBRAZE® PC/PLC controls

/ Customized heating systems: electrical or gas

/ Energy saving designs

Controlled Atmosphere Brazing Process

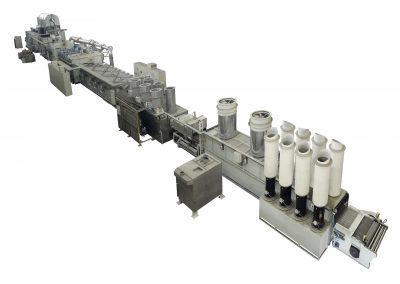

A fully configured CAB furnace system includes thermal degreaser with afterburner, a fluxer unit, a dry off oven, and the CAB furnace. Or, in the case of the precoated or flux fewer cores systems limited to degreasing/debinding oven and the CAB furnace only.

These systems can be configured in an in-line, a continuous rectangular line, a U-shaped line or Batch systems to meet your plant’s installation space requirements.

Since flux is noncorrosive

/ Less capital intensive

Compared to vacuum brazing

/ High Brazing Quality

Due to clean nitrogen atmosphere, process uniformity, sharp heating and cooling profiles

/ Brazing R&D on your own aluminum heat exchangers:

Reduce your investment risk by taking advantage of the SECO/WARWICK Brazing Center.

/ HVAC

/ Power Generators and Electric Power Plants

/ Aerospace

/ Railways

/ Electronics

/ Household equipment

/ Thermal afterburner to reduce VOC emissions for degreasers,

/ Scrubber with active aluminum oxide deposit to reduce the emission of hydrogen fluoride generated during brazing process,

/ For gas-heated solutions, energy recovery systems reducing gas consumption and thus CO2 emissions:

- energy exchange system between the thermal afterburner and degreasers,

- energy recovery from the preheat chambers and brazing furnace by transferring exhaust gases under the inlet tunnel and further as support for the Dryer heating system.

/ Electric heating systems instead of gas heating systems (including modification of current equipment) to reduce CO2 emissions.

/ Optional applications of high-performance microporous insulation to reduce heat losses and thus reduce energy consumption (in case of gas heating systems – reduction of CO2 emissions).

/ Heated curtains inlet tunnel to limit the conveyor belt and load temperature drop during the transfer, and thus shortening the reheating time – in the overall balance, lowering energy consumption (in case of gas heating systems – reduction of CO2 emissions).

/ A common conveyor belt for the dryer (or TTBB) and the furnace to reduce the energy consumption associated with double heating in case of separate systems (in case of gas heating systems – reduction of CO2 emissions).

/ The customer uses energy emitted by the cooling chambers’ and the dryer’s extraction systems to support the plant installations’ heating.

/ Non-emission cooling systems based on air jacket instead of a closed water circuit.

/ Control – IDLE and WEEKEND furnaces operating modes lowering the operating temperature and turning the furnace off when it is not needed during production breaks – lowering energy consumption (in case of gas heating systems – reducing CO2 emissions).