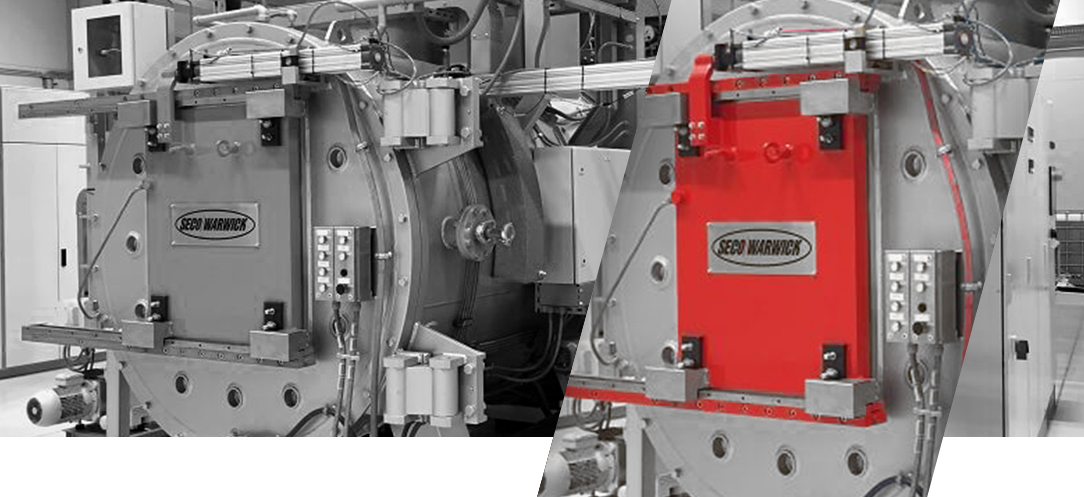

Triple chamber vacuum furnace for low pressure carburizing (LPC) and high pressure gas quenching in semi-continuous production mode – CaseMaster Evolution® T

Cost-effective surface hardening by low pressure carburizing (LPC) and high pressure gas quenching in a triple chamber vacuum furnace.

The CaseMaster Evolution T replaces today’s conventional semi-continuous processes under protective atmosphere followed by oil quenching, for truly vacuum heat treatment with low pressure carburizing and nitrogen gas quenching resulting in precision and replicability, and allows for the adaptation to modern industry requirements.

The CaseMaster Evolution T is a triple-chamber vacuum furnace designed for high volume case hardening processing based on low pressure carburizing (LPC) and gas quenching in the semi-continuous production mode. It is built of three separated, functional chambers: loading and pre-heating chamber, process chamber (LPC), gas quenching and unloading chamber.

It’s designated for heat processing of variety of components and steel grades commonly carried out in traditional equipment. The triple chamber furnace provides vacuum and gas quenching quality as well as high throughput.

The CaseMaster Evolution T is modern and reasonable alternative for the traditional devices with truly vacuum heat treatment meeting the modern industry requirements.

Contrary to double- and single-chamber furnaces, at the triple-chamber furnace the loads pass through the next chambers one-by-one in the semi-continuous mode. At the same time, three batches are found together in the furnace (one piece in each chamber) and the working cycle of the furnace is determined by the longest cycle in one of the chambers (usually in the process chamber). In comparison to the double-chamber furnaces, the triple-chamber furnaces can reach even twice throughput.

The CaseMaster Evolution T can replace the classic sealed quench furnaces and lines for high-volume production such as pusher, roller or rotary furnaces. It is distinguished by a significant improvement of the process result quality, capacity and production flexibility, and the compact system. Obtained technological results considerably exceed the traditional technology achievements with respect to accuracy, evenness and repeatability of the hardened layer shaping, and eliminates of the IGO problem.

It can be installed directly in production halls (it does not require any separated area) and meets safety and environment protection requirements. The capacity of the single furnace can reach even up to 200 kg/h and it can be multiplied by using groups of many furnaces. The group of many furnaces can be easily supplemented for fully-automated loading and unloading system at the later stage of development, when it is fund necessary.

The direct costs of the process are within the range of traditional technology costs.

The CMe T type furnace is also an attractive alternative for modular vacuum systems for mass production. The advantages include initial capital costs as well as operating independence and flexibility.

It works in semi-continuous mode, loaded from one side and unload from another. The furnace treats 3 loads at the same time in a very efficient way. All these result in significant increases in a furnace throughput, as much as twice or even triple times comparing to single- or double-chamber furnaces.

- Fully automated processing

- Vacuum, horizontal, triple-chamber

- Graphite heating chamber

- Low heat losses by increased thermal insulation

- Low pressure carburizing (LPC)

- Oil or high pressure gas quenching, nitrogen (N2) or helium (He) 24 bar

- Vacuum and pressure tight inner doors ensure high purity of process and parts

- Short workload-transport time within the furnace

- Shorter evacuation times by independent pumping systems for each chamber

- Uniform quenching and distortion reducing by stepless control of oil circulation system

- Compact, modular design

High Production Efficiency

/ High volume production – semi-continuous

/ Low process cost comparable with traditional technology

/ Fast and efficient LPC

/ Operational flexibility on demand,

/ Fully automated, semi-continuous operation

/ Independent device, which can be freely expanded (multiplied) to increase the production efficiency

/ Accessibility easy and fast

/ Minimizes final/hard machining costs

Outstanding Quality

/ High precision and reliability of results

/ Ideal surface condition

/ Elimination of oxidation and IGO

Safety and environment

/ Safe (no open fire and explosion risk)

/ Reducing utility consumption

/ Low emission of heat and gases

/ Eliminates oils, chemicals, and washer systems

/ Clean and environmentally friendly technology

The solution determines an evolutionary direction of changes and development of heat treatment technology and equipment for the modern industry and fully complies with present and upcoming requirements.

/ Automotive

/ Aviation

/ Heat exchanger

/ Bearing

/ Machine-building

/ Commercial Heat Treatment

/ Quenching,

/ Brazing,

/ Annealing.

/ Carburizing grades,

/ Stainless steels,

/ Specialty steels and alloys

/ elimination of quenching oil and contamination, washers and cleaning chemicals,

/ environmentally friendly process,

/ no emission of climate-warming gas Co₂,

/ fast and uniform LPC of densely pack loads,

/ nitrogen quench (neither oil nor helium is needed),

/ high lifespan of hot zone components – graphite,

/ no emission of harmful gases (CO, NOx),

/ safe, no flammable and poisonous atmosphere,

/ no decarburization or oxidation, elimination of IGO,

/ flexible, on-demand operation,

/ no open fire.