DO YOU KNOW

How to carburize

thick layers in a vacuum

pit furnace?

www.secowarwick.com

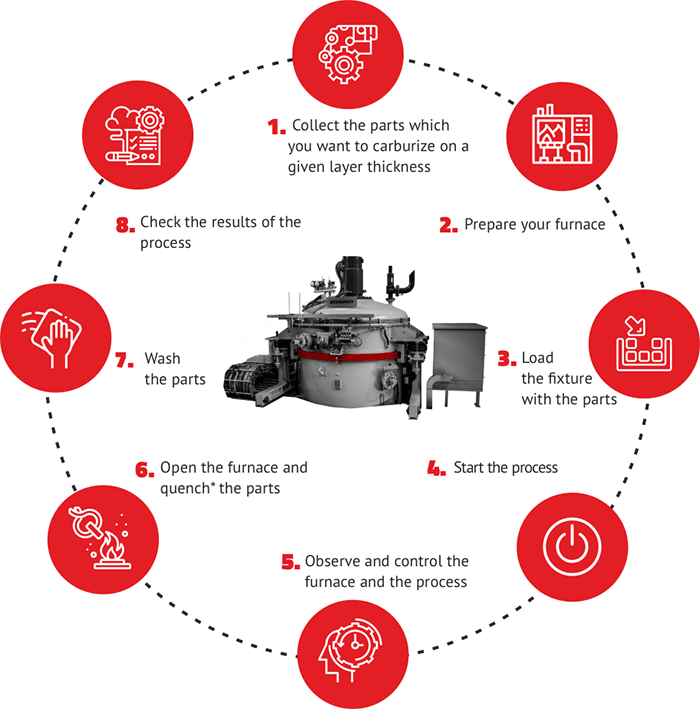

1. Collect the parts which you want to carburize on a given layer thickness

- Thoroughly clean the parts and remove any residue left after machining.

- Estimate the surface area of your parts with the help of SECO/WARWICK’s user-friendly software.

- Place the parts on a dedicated fixture; make sure that the fixture is ready to withstand elevated temperatures.

2. Prepare your furnace

- Make sure that the furnace has been well maintained in accordance with the instruction manual.

- Ensure utilities are connected (No endogas generator needed; Pit uses only acetylene mixture).

- Choose your ideal vacuum carburizing recipe to achieve maximum savings on process time.

- Start your furnace immediately. No conditioning necessary!

3. Load the fixture with the parts

- Open the furnace (mind the temperature if the furnace is opened in hot conditions).

- Use the overhead crane to load the fixture with the parts into the furnace (this process can be automated).

- Close the furnace.

4. Start the process

- Start the process using either the furnace’s built-in HMI or a remote SCADA control system.

- Control system of the vacuum pit furnace archives thousands of recipes in the database with immediate access.

5. Observe and control the furnace and the process

- While the furnace is fully automatic, it is advisable to periodically monitor conditions using the HMI or remote control.

- Preventive maintenance features provide insight into every key sub-assembly of the furnace.

- Optional cloud data storage provides limitless archiving possibilities.

6. Open the furnace and quench the parts

- Open the furnace (caution: 1050°C is really hot).

- Remove the fixture with parts using the overhead crane and place it in a quench bath (this can be automated); alternately, leave them in the Pit to cool using its built-in quenching system.

- Load the next batch or shut down the furnace. No constant temperature conditioning necessary.

7. Wash the parts

- After the quenching process, place the fixture with the parts in a washing machine.

8. Check the results of the process

- Check if the obtained results correspond with your requirements.

- Admire uniform effective case depth [ECD] and the fact that there is no intergranular oxidation [IGO] in your parts.

- Calculate your savings gained in comparison with traditional atmosphere pit carburizing furnace.