HEAT RECOVERY FROM AN INDUSTRIAL FURNACE

The green trend in the economy is becoming increasingly visible, which is why our customers are successively looking for solutions allowing them to save utilities and thus show that they are using green technology. They will not replace the furnace due to the cost, so an economical solution may be to equip the hardening plant with an installation allowing the use of waste heat produced.

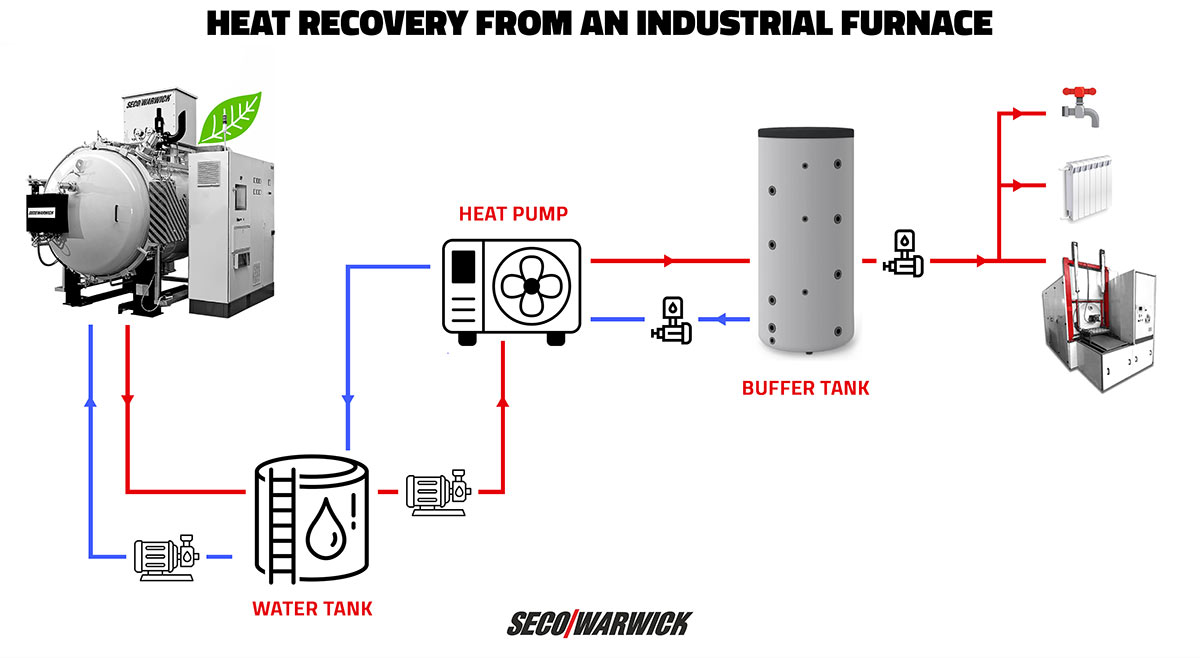

This process involves capturing the heat generated during heat treatment processes and using it to power other production processes, heating rooms and hot utility water. This not only helps reduce energy costs, become independent from gas supplies, but also brings benefits to the environment, e.g., reducing CO₂ emissions. It also allows to avoid severe penalties and improve the company’s image.

Heat recovery from an industrial furnace involves recovering and reusing energy generated during metal heat treatment.

/HEAT RECOVERY PURPOSE

Increasing the plants or hardening plant’s entire production process energy efficiency.

Energy recovery from heat treatment processes is possible for most furnaces. Considering the SECO/WARWICK’s activity profile, we are currently focusing on medium and small furnaces, and in particular vacuum furnaces. Until recently, these types of furnaces were not considered in terms of energy recovery possibility. Current trends in energy saving have forced us to find appropriate ecological solutions also for these units.

/RECOVERED HEAT APPLICATION

- Heating buildings (halls, facilities).

- Heating hot water.

- Waste heat recovered in the heat treatment process can be used for other production processes conducted in the plant, e.g., in washing equipment.

- Conversion of heat into cold for cooling rooms.

/BENEFITS

- Reduced overall energy costs in the plant, by reusing it in other production processes.

- Becoming independent of gas supplies for heating buildings and heating domestic hot water.

- Reduction of CO₂ emissions.

- Avoiding severe penalties related to this.

- Building the image of a company which cares for the environment and reduces its carbon footprint.

The process of implementing a heat recovery installation is like other technical tasks of this type. The implementation time depends on the designed installation’s size and the system components’ complexity.

PROCESS STAGES

- Detailed technical assessment of the current state together with collecting the necessary data.

- Development of a technical solution concept together with the potential benefits’ and implementation costs’ estimate.

- Deciding on implementation – order.

- Completing the necessary installation elements, establishing a work schedule.

- Installation at the plant, start-up, tests.

Need detailed information?

Contact us now.

What is heat recovery from an industrial furnace?

Heat recovery from an industrial furnace involves recovering and reusing energy generated during metal heat treatment. The use of this type of technology is intended to increase the energy efficiency of the entire production process within a manufacturing facility or commercial heat treating plant.

What can be done with the recovered heat?

The most common use of recovered heat is heating buildings (halls, facilities) and heating domestic hot water. Waste heat that is recovered in the heat treatment process can also be used for other production processes carried out in the plant, e.g. washing equipment. Another interesting option is to convert heat into cold for cooling rooms.

What will you gain from heat recovery from a furnace?

Recovering heat generated during metal heat treatment processes helps reduce the overall energy costs in the plant by reusing it in other production processes. It also allows users to become independent from gas supplies for heating buildings and heating domestic hot water. It brings benefits to the environment by reducing CO₂ emissions and to avoid the severe penalties associated with it. In addition to clear economic benefits, it undoubtedly influences the image of a company caring for the environment and reducing its carbon footprint.

Which industrial furnaces can be equipped with a heat recovery system?

Energy recovery from heat treatment processes is possible for most furnaces. Considering the SECO/WARWICK’s activity profile, we are currently focusing on medium and small furnaces, and in particular, vacuum furnaces. Until recently, offers for these types of furnaces did not include an energy recovery option. Current trends in energy saving have forced us to find appropriate ecological solutions for these units as well.

Does SECO/WARWICK perform heat recovery installations on other manufacturer’s furnaces?

Yes, it is possible to perform an installation on furnaces other than SECO/WARWICK’s brand. We can also design and implement an appropriate installation for units from other manufacturers of industrial furnaces.

The ability to implement this type of solution is decided individually for each project.

How long does the heat recovery installation take?

The process of implementing a heat recovery installation is similar to other technical tasks of this type. The implementation time depends on the designed installation’s size and the system complexity.

The following steps in the process are:

- the current condition’s detailed technical assessment together with collecting the necessary data,

- development of a technical solution concept together with potential benefits and an implementation cost estimate,

- the decision on implementation – ordering,

- completing the installation’s necessary elements, establishing a work schedule,

- installation at the plant, start-up, tests.

Will the modernization mean downtime for the furnace?

The furnace downtime depends on the project’s complexity and the selection of a specific heat recovery solution. Most of the work can be performed without interfering with the furnace’s daily operation. The furnace shutdown will be related to the need to connect a ready-made heat recovery system to the existing equipment, including the start-up and acceptance test phase. The necessary downtimes are planned so as to disrupt the furnace’s normal operation schedule as little as possible.

Is the heat recovery solution safe?

The proposed installations are completely safe both in terms of health & safety, and the furnaces themselves. The project assumption is not to change the furnace operation system, but to expand its external components with the capacity for heat recovery, e.g. from the cooling system. The furnace control system will continuously monitor the furnace’s correct operation, and in emergency situations requiring, e.g. additional cooling, it will switch from one system to another in order to ensure the furnace’s safe operation.

Can a heat recovery installation be performed on a furnace under warranty?

For SECO/WARWICK furnaces, the warranty will be maintained. In the case of furnaces from other manufacturers, it will require the manufacturer’s consent or the installation after the warranty period has expired.

I am interested in the heat recovery option, what do I have to do now? What are the next steps?

The next step is to contact our company to arrange a technical meeting at the customer’s facility.

At your disposal is:

Sebastian Ostasz – Key Account Manager Central European Countries.

E-mail:

Mob: +48 517 808 494