OEE

Monitor and analyze furnace productivity and utilization

Monitor and analyze furnace productivity and utilization

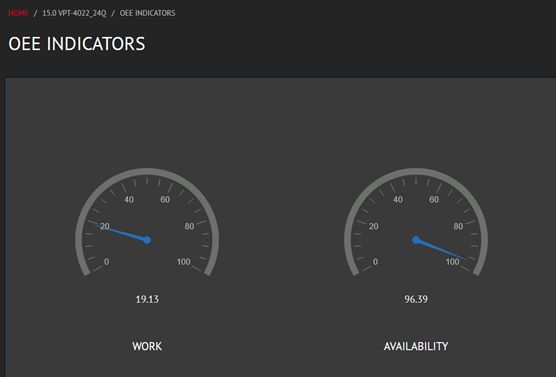

OEE – (Overall Equipment Effectiveness) is a measure of machine efficiency used in production management. OEE is an indicator determining the extent to which machines (in this case, industrial furnaces) are used in the production process, and how effectively they are able to perform their tasks.

This module allows users to calculate the “Work” and “Availability” indicator values for a given furnace, in any selected time range. The percentage distribution of the indicators that confirm the state of the furnace are also displayed, providing additional data to calculate the effectiveness of the equipment.

/ Assessment of furnace condition and use,

/ Assessment of the implemented solutions aimed at improving the furnace availability,

/ Ease of production planning,

/ Production optimization.

OEE- BENEFITS

/ Precise calculation and presentation of indicators showing the furnace utilization, which is crucial for assessing its effectiveness and efficiency.

/ A general assessment of the furnace condition allowing for a quick response to possible problems.

/ Assessment of the implemented solution’s effectiveness translates into enhanced furnace availability and the production process’s continuous improvement.

/ The OEE module facilitates production planning and optimization of resource use.

/ By monitoring furnace operation and identifying areas requiring optimization, the OEE module facilitates the effective use of each furnace’s.

/ The module allows users to check the effectiveness of implemented solutions.