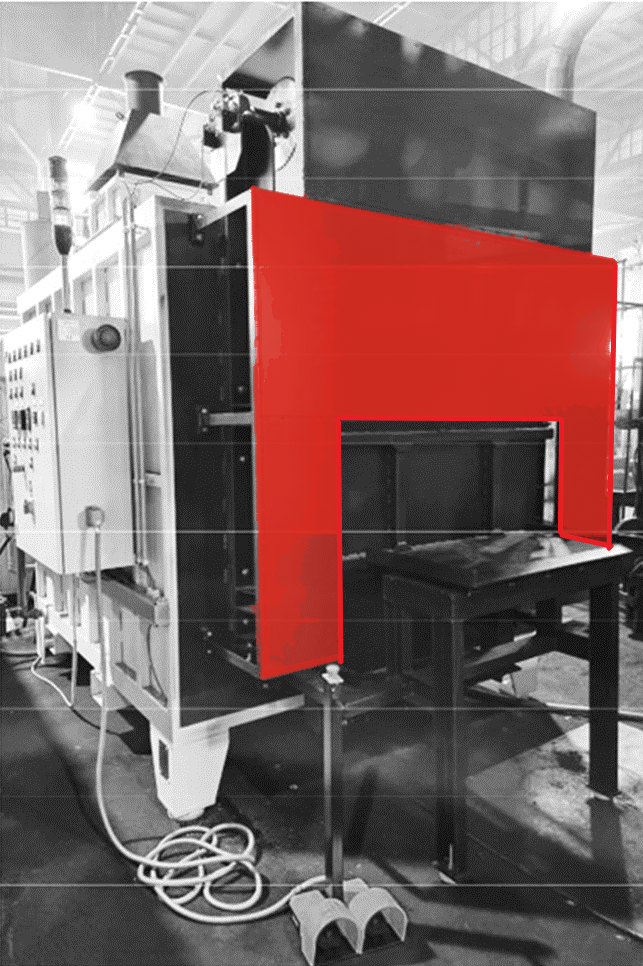

FORGING CHAMBER FURNACE

TYPE IPT

Gas chamber forging furnace designed for heating steel parts placed directly on the furnace shaft at a maximum temperature of up to 1300 degrees C in a flue gas atmosphere.

General information:

/ gas chamber forging furnace

/ Manufacturer Industrial Process Technology

/ Year of production: 2021

/ Location: Southern Poland

/ Furnace disconnected- ready for relocation

/ Condition: the furnace has not performed a single process other than start-up after the first installation.

/ We offer technical evaluation, relocation and installation of the unit at the destination on the E.U. territory.

Technical data

| Batch window dimensions: | ||

| Width | 800 | mm |

| Height | 400 | mm |

| Usable space dimensions: | ||

| Width | 800 | mm |

| Height | 300 | mm |

| Length | 1200 | mm |

| Maximum stem load | 800 | kg |

| Maximum furnace capacity | 400 | kg/h |

| Overall dimensions of the furnace including installations and control cabinet: | ||

| Width | ~3 000 | mm |

| Height | ~4 500 | mm |

| Length | ~4 800 | mm |

| Furnace weight | ~9 800 | kg |

| Loading method | manual | |

| Loading level | ~1 100 | mm |

| Rated temperature of the furnace | 1 300 | °C |

| Recommended operating temperature of the furnace | 1 280 | °C |

| Heating speed of empty furnace | 150 | °C/h |

| Type of atmosphere | exhaust | |

Electricity: |

||

| – power supply: | 3/N/PE 400/230 | V AC |

| – frequency: | 50 | Hz |

| – control circuits: | 24 | V DC |

| Installed electrical power | ~4 | kW |

Heating system: |

||

| – number of heating zones: |

1 |

|

| – type of burners: |

BIO65HB-400/335-(34)E |

|

| – total number of burners: | 2 | pcs. |

| – heating power of burners: | 180 | kW |

| – recommended heating power adjustment range: | ||

| – minimum power: | ~19 | kW |

| – maximum power: | ~75 | kW |

| – natural gas type: | (E) or GZ50 | |

| – pressure at the connection: | 250 | mbar |

| – connection size: | 1½” | |

| – connection capacity: | ~30 | m3/h |

| Thermal door of the furnace: | ||

| – furnace door drive: | electromechanical, | |

| – door opening/closing direction: | up/down | |