General information:

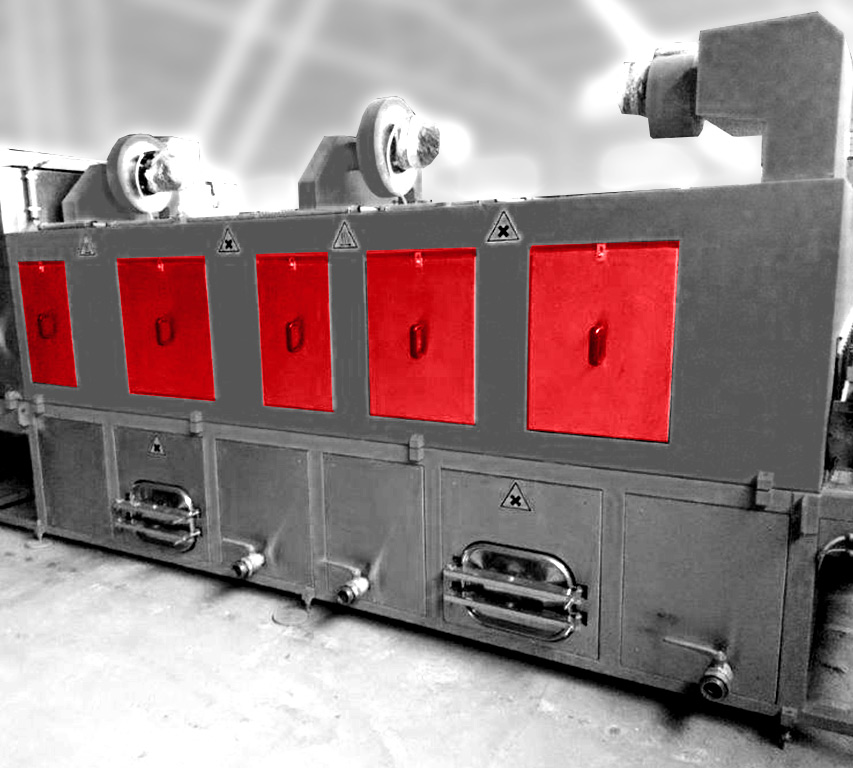

/ Washing roller machine with washing, rinsing and drying

/ Manufacturer: ILVET s.r.l.

/ Year of production 2013

/ Location – Poland – SECO/WARWICK’s Warehouse

/ The unit is out of use: connection and testing possible

/ Condition: Very good. The unit has never operated – the customer canceled the contract. The washing machine is dedicated to continuous operation – bearing rings with the possibility of adaptation to other production processes.

We offer technical assessment, relocation and assembly of the unit at its final location within the E.U. as well as adaptation to the Customer’s specific equipment/processes.

Technical data:

| BUILDING MATERIAL | Aisi 304 stainless steel, for the parts which are in contact with the treatment phases , carbon steel for the others |

| PIECES TO BE TREATED | Pieces in Fe (rings) |

| DIMENSIONS OF THE PIECES | Min 180 mm, H= 10 mm, max 400 mm H= 170 mm max |

| PRODUCTION PER HOUR | 750 KG |

| POLLUTANT | Oil |

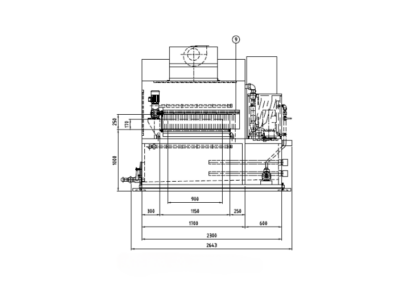

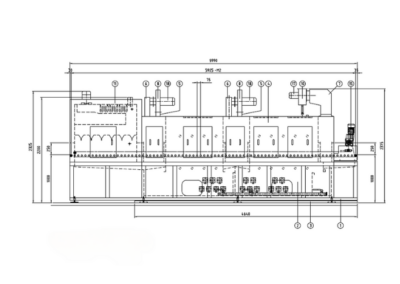

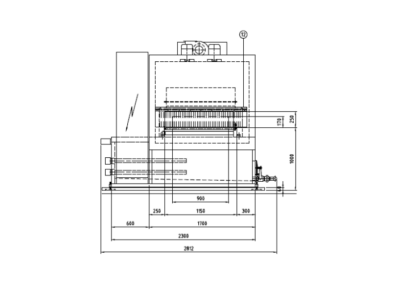

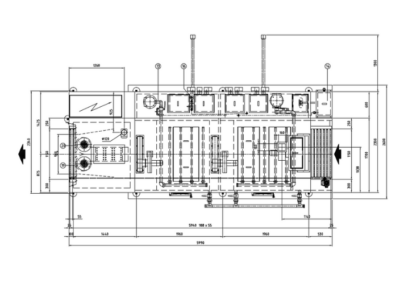

| VOLUME DIMENSIONS | See DRAWING C-1327L2 |

| PASSAGE OPENING | 1100 mm x H 300 |

| NOMINAL ROTATIONAL SPEED OF THE CYLINDER | Step by step advancement, variable length, advancement speed 8 mt/1′ |

| NECESSARY WATER | Ca. 3800 Liters |

| ELECTRIC FEEDING | 400/V 3PH + N – Frequency 50Hz |

| AUXILIARY CIRCUITS | 24V DC |

| THERMAL INSTALLED POWER | 153kW |

| ELECTRICAL INSTALLED POWER | 7.1KW |

| WEIGHT | 4200 KG |

| LOADING | At customer’s charge, with conveyor |

| UNLOADING | At customer’s charge with conveyor |

WORKING CYCLE

| PHASE | DESCRIPTION | TIME | TEMP oC |

| LOADING |

To be carried out by the customer, the movement in the treatment zones is carried out with motorized rollers

|

||

| SPRAY WASHING | recycled with pump | 12’ | 80 |

| DRIPPING | With blowing during the passage | Room temp. | |

| SPRAY RINSING | recycled with pump | 12’ | 60 |

| DRIPPING | With blowing during the passage | Room temp. | |

| DRYING | with recycled air, heated electrically | 12’ | 130 |

| All treatment times, temperatures and advancement speeds can be regulated | |||