ALARMS

Stay up-to-date checking alarm statistics, historical and current alarms and warnings.

Stay up-to-date checking alarm statistics, historical and current alarms and warnings.

Alarms is a module allowing to check the historical alarm statistics of a given device. The user has a full view of active alarms and warnings and access to their history in a configurable time range.

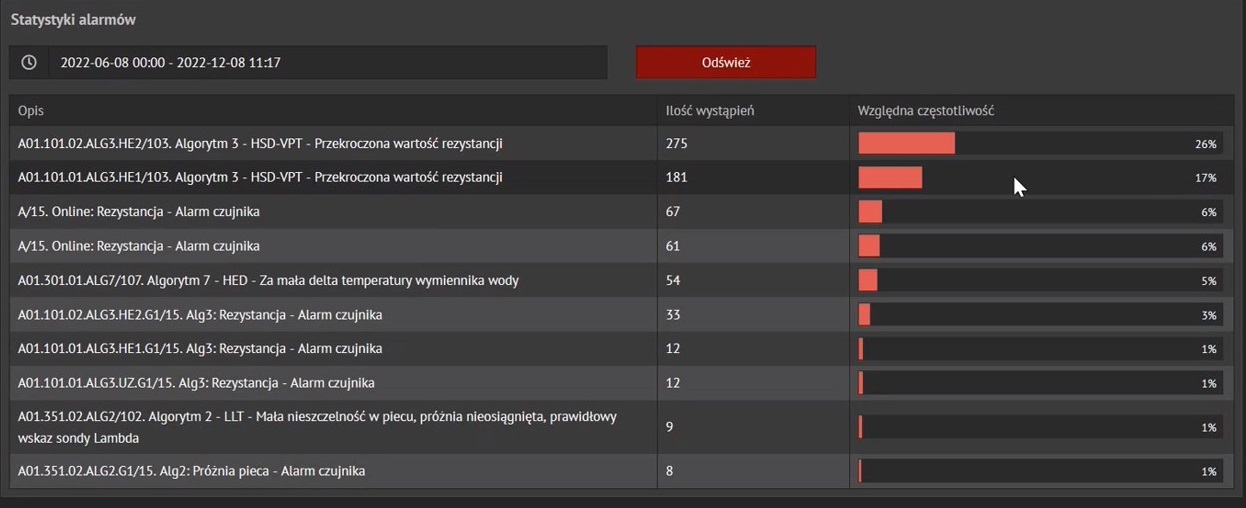

The alarm statistics show the 10 most frequent alarms in a given time range. The statistics are presented in the form of a table where you can see; the alarm description, number of occurrences in a given time interval and relative frequency (presentation of alarm occurrences in a graphical and numerical way in relation to all alarms expressed as a percentage).

The module main functions are

/ possibility to review all alarms and warnings on the furnace,

/ possibility to review all alarms and warnings from the Seco/Predictive module resulting from individual algorithms,

/ email notifications-> when an alarm or warning is generated,

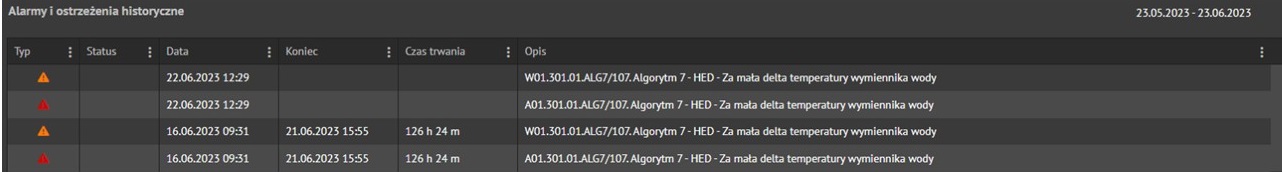

/ selecting the alarm confirmation type (“Undefined” – no alarm confirmation, “Correct” – alarm display in accordance with the device status, “Incorrect” – the alarm should not appear) and insert your own comment.

Alarms display

/ from the Seco/Predictive module (alarms and warnings resulting from individual algorithms – e.g. Exceeded resistance value),

/ from the furnace (e.g. Gauge damage).

ALARMS – BENEFITS

/ Corrective actions: Recognize common problems and take quick corrective actions.

/ Easily identifying the most common problems means preparing for possible failures and minimizing downtime.

/ Production safety: Tracking irregularities permits users to make an appropriate response, increasing the safety and continuity of the furnace operation and the production process.

/ Monitoring: thanks to access to important information, users can quickly identify potential problems and solve them.

/ Access to information about failures without physical presence at the furnace means:

– Security: ability to remotely monitor the furnace status, which enables users to quickly respond in the event of a failure or irregularity.

– Time-saving: access to information eliminates the need to inspect the furnace in person and quickly assess whether and what type of action is required.

– Efficiency: supervisors can concentrate on other tasks while monitoring furnace status.