SKANA ALUMINUM PURCHASES HIGH CAPACITY EXOGAS™ ATMOSPHERE GENERATOR AND DRIERS

SECO/WARWICK USA, an American SECO/WARWICK Group subsidiary, has recently been awarded a contract to supply Skana Aluminum Company in Manitowoc, Wisconsin with an Exogas™ Exothermic Atmosphere Generator. The atmosphere generator provides an indirect-chilled exothermic atmosphere for annealing, brazing, normalizing, drawing,…

50 years of business and science history

In the SECO/WARWICK Group, innovation is the basis of development. This is the result of cooperation with the scientific community and the higher education sector. The SECO/WARWICK’s most important scientific Partner celebrates their 50th anniversary in the Materials Engineering field…

Swedish GreenIron H2 AB and SECO/WARWICK furnaces – a joint opportunity for carbon footprint reduction

SECO/WARWICK has signed a final agreement with GreenIron H2 AB for the delivery of a series of furnaces for processing metals from post-production waste without the use of fossil fuels. The most unique project in the field of green technologies…

NASA and F1 partner chooses SECO/WARWICK solutions for the fourth time

A European supplier of aviation and defense industry components, NASA and Formula 1 partner has chosen SECO/WARWICK for the fourth time. This recent purchase is for a CaseMaster Evolution® horizontal two-chamber furnace with oil quenching and LPC. CaseMaster Evolution is…

Medical implant hardening in a SECO/WARWICK furnace

SECO/WARWICK will supply a Vector® vacuum furnace to the Marle Group, a global manufacturer of orthopedic prostheses. The furnace on order will be used for the heat treatment of cobalt implants. Demanding heat treatment requirements for cobalt alloys Cobalt alloy…

Cooperation between Retech and GeniCore in the area of spark plasma sintering

Retech, an American subsidiary of the SECO/WARWICK Group, has established cooperation with GeniCore, a company dealing in composite materials engineering. Thanks to the cooperation, Retech will expand its offer in powder metal processes with spark plasma sintering. The Spark Plasma…

Service hardening plant in Spain buys another SECO/WARWICK furnace

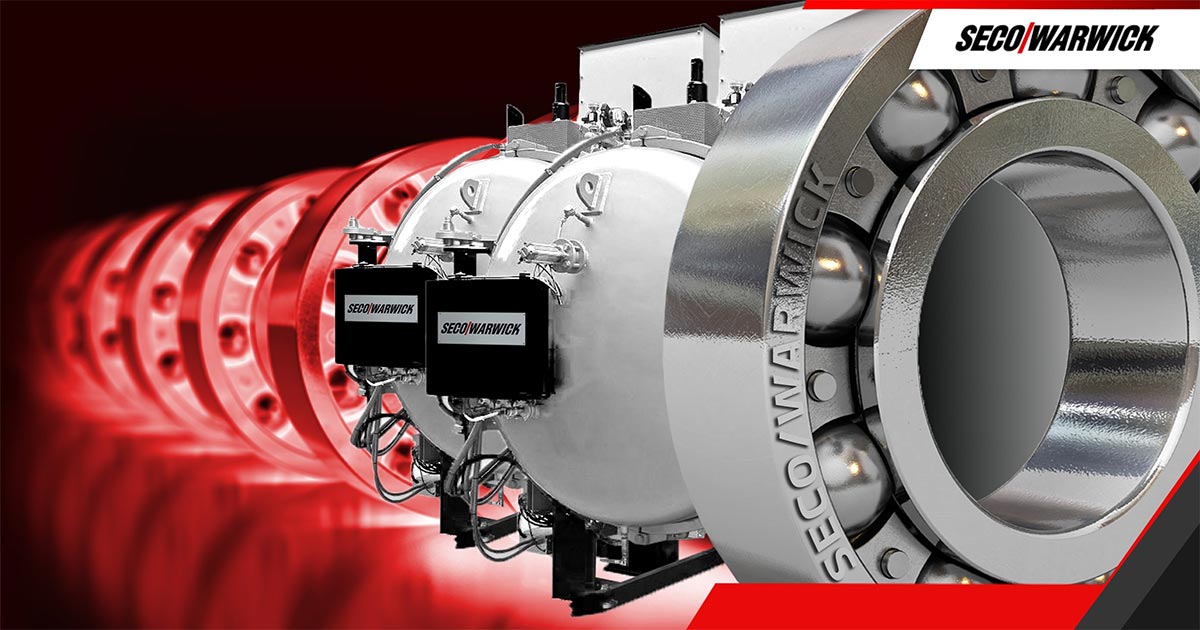

One of the largest service hardening plants in Spain has purchased a Vector® vacuum furnace from SECO/WARWICK. It will be the third SECO/WARWICK solution for this Partner. The Client has been cooperating with SECO/WARWICK for many years, along with Arrola,…

Special fasteners to be processed in a SECO/WARWICK vacuum furnace

The plant producing highly advanced fasteners for the largest manufacturers in the aerospace industry, operating since the middle of the last century, ordered a Vector® vacuum furnace from SECO/WARWICK. The furnace will be delivered in a standard configuration and will…

Jet engine repair with SECO/WARWICK in Serbia

SECO/WARWICK will supply an industry leader providing maintenance and repair services for jet engines with a vertical vacuum furnace with bottom-loading and gas cooling. The Vector® vacuum furnace will be used to process components for civil aircraft jet engines. Thanks…

A “Green” SECO/WARWICK vacuum furnace for a manufacturer of wind power plants

A recognized manufacturer of wind power plants has chosen a vertical vacuum furnace from SECO/WARWICK designed to perform low-pressure carburizing for the large structural elements (gearboxes) used in wind power plants. One furnace, two technologies The solution on order combines the…