Aerospace industry supplier benefits from SECO/WARWICK proprietary Atmosphere Generator

SECO/WARWICK provided an additional atmosphere generator system to a supplier of engineered carbon and graphite solutions for severe service lubrication applications in the aerospace, petrochemical, energy, industrial, and defense sectors. The 6,000 cubic foot per hour rich exothermic generator, a…

SECO/WARWICK significantly extends the productive life of precious metals supplier’s key piece of equipment

SECO/WARWICK comprehensively updated and simultaneously extended a box furnace’s productive longevity, which is a pivotal piece of manufacturing equipment for a leading international participant in the field of precious metals and advanced materials.

Rotary retort furnace – the 2018 atmosphere heat treatment star

The Rotary retort technology is designed to produce consistently superior quench hardening performance that is required for fast, economical, uniform heat treating of small parts. It provides the process flexibility to be utilized for either single or multi-application production. Ideal…

ZeroFlow® Gas Nitriding Furnace Gives Transportation Industry Manufacturer A Competitive Edge

A growing American manufacturer has recently ordered a new precision gas nitriding furnace with ZeroFlow® from SECO/VACUUM (SVT), a SECO/WARWICK Group company.

Manufacturer of matrix forgings and construction connectors selects SECO/WARWICK as the technology supplier

KUŹNIA Sułkowice S.A., renowned Polish manufacturer of high quality matrix forgings, construction connectors and manual tools manufactured with their own forgings, continues to select SECO/WARWICK as their technology supplier.

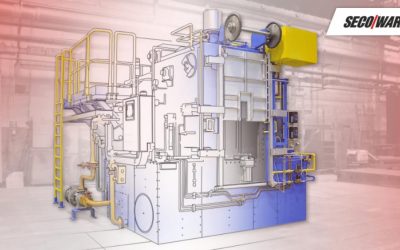

New SECO/WARWICK line for hardening and carbonitriding goes to Gaweł Screw Production Plant

SECO/WARWICK will supply a type ATE technological line, consisting of a PTE muffle belt furnace designed primarily for carbonitriding, washing and annealing.

Giants of manufacturing extend their cooperation in heat treatment technologies

ŚRUBENA-UNIA SA, one of the leading manufacturers of industrial fasteners in Poland and in Europe, will increase its production capacity with a new SECO/WARWICK high-tech, ACLE line. The ACLE line is a cast link furnace system designed for hardening screws…

BELAZ, manufacturer of the world’s largest vehicle, selects SECO/WARWICK as a technology provider

BELAZ, Belarusian manufacturer of heavy-duty trucks, chose a SECO/WARWICK heat treatment system utilizing a roller hearth furnace line for press hardening large diametrical bearing rings used in heavy duty truck production.

Innovative heat treatment solutions to the ASM Heat Treat show

Pawel Wyrzykowski, CEO of SECO/WARWICK Group, announced today the company’s plans for the upcoming ASM Heat Treating Conference and Exposition. According to Mr. Wyrzykowski, the company’s “commitment to innovation and precision design and manufacturing will be evident in both our…