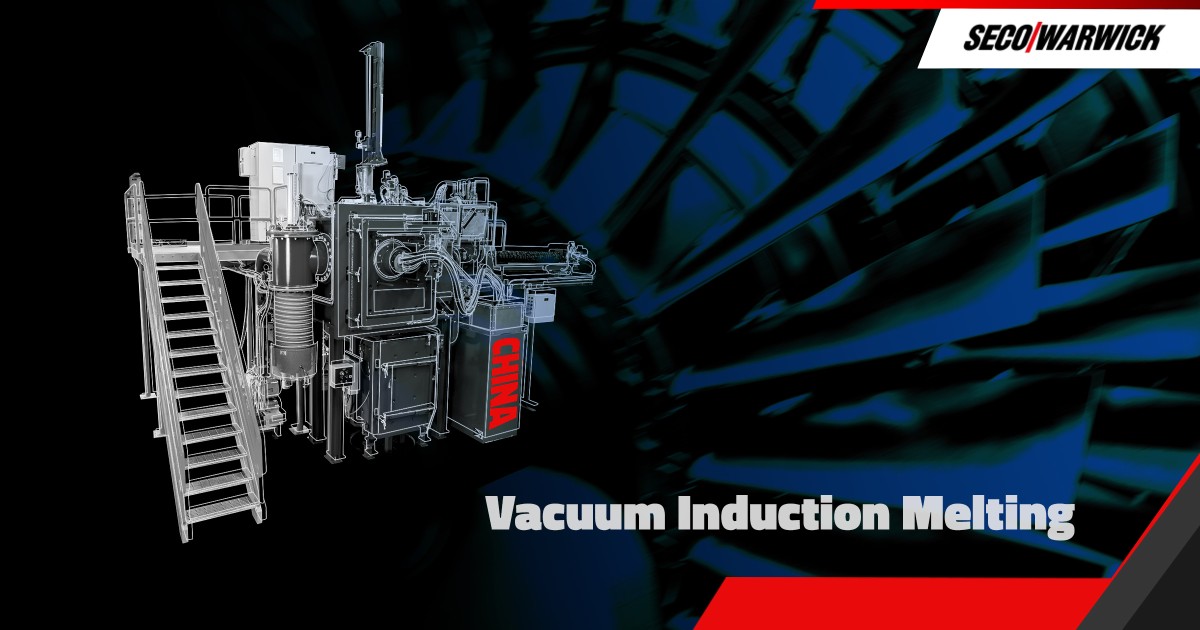

A Chinese Partner has purchased a two-chamber VIM furnace with a 50 kg loading capacity for casting gas turbine blades from SECO/WARWICK. The solution has already obtained an export license and will soon be delivered to China.

The VIM furnace – the most frequently chosen solution in the vacuum metallurgy field

The solution on order is a VIM 50 kg induction furnace. It will produce gas turbine blade castings in an equiaxed structure. The furnace is unique due to its extremely high level of automation. It is one of the most frequently chosen solutions in the vacuum metallurgy field due to its innovativeness, reliability, and, thanks to a modern recipe system, process repeatability. It is distinguished by an innovative control system and precise melting temperature control.

Various metals can be processed in vacuum metallurgy furnaces, including titanium and its alloys, tantalum, tungsten, niobium, zirconium, silicon, nickel, and cobalt alloys. The solution ordered by the Partner will be able to melt alloys of non-reactive metals, specifically nickel.

“The growing popularity of VIM furnaces and the increasing importance of vacuum metallurgy is a consequence of the heavy industrial production needs for constant change. We see a large increase in the demand for products from this segment throughout Asia. Thanks to the cooperation among our companies within the SECO/WARWICK Group, we can supply induction furnaces all over the world. Our reliable service is also important. According to recent research, as many as 98 percent of our customers recommend SECO/WARWICK after-sales services,” said Sławomir Tomaszewski, SECO/WARWICK Vacuum Melting Team Director.

“This Partner already owns our equipment from the vacuum segment. We are glad that this time we also decided to cooperate with vacuum metallurgy technology,” added Michał Litwin, Sales Manager from the SECO/WARWICK Vacuum Melting Furnaces Team.

Gas turbines — Leonardo da Vinci’s invention that changed the industry

It is difficult to imagine the modern world without the gas turbine. This device revolutionized industry, energy, and transport, giving people a powerful energy source.

A gas turbine is an internal combustion rotary heat engine that operates using liquid gas fuel or a dual-fuel system. The turbine’s main element is a movable shaft with blades that are struck by the compressed gas, driving the entire unit operation. The principle of its operation is to suck in cold gas, compress it, heat it (by burning fuel), and then push it into the turbine, i.e., a shaft enclosed with blades, which, due to the gas expansion, starts to rotate and produce — using a generator — energy. The above process can be simplified as follows — the turbine works like a wheel in a water mill, with the difference that the installation is moved by compressed and heated gas (e.g., steam) instead of water.

The gas turbine operation is based on simple laws of physics. Their mechanics were initially developed in ancient Greece by Heron of Alexandria. In turn, in 1500, sketches of a steam turbine, which could be mounted on home chimneys, were made by Leonardo da Vinci. It was only during the industrial revolution that humanity learned to use the potential of this solution. The first gas turbine engine was patented in 1791. This solution was used to power ships a little over a hundred years later. In 1918, turbine wholesale production began, which helped revolutionize the energy industry. In turn, in 1930, gas turbines began to power aviation. Today, gas turbines are an essential element in many sectors. Their service life depends largely on the blades cast in SECO/WARWICK VIM furnaces. Thanks to precise and repeatable operation, SECO/WARWICK furnaces from the vacuum metallurgy segment ensure an excellent final product with a long service life.

“In the aviation industry, state-of-the-art jet engines use advanced single-crystalline cast blades. The VIM furnace is famous for its high efficiency and low operating costs. The user-friendly control system ensures precise processes: casting, temperature control, as well as comprehensive data collection. These are some of the advantages of this unique solution. Thanks to its design, it ensures high repeatability and unrivaled throughput. New orders for VIM furnaces on the Asian market signal its recovery. We strongly focus our activities on this region of the world, taking care not only to provide efficient equipment for metallurgy and metal heat treatment but also to ensure the highest quality of service,” commented Sławomir Woźniak, the CEO of SECO/WARWICK Group.