CASEMASTER EVOLUTION

Unique technology uses high temperature and low pressure carburizing to replace conventional sealed quench furnaces by achieving shorter cycle times and higher production rates

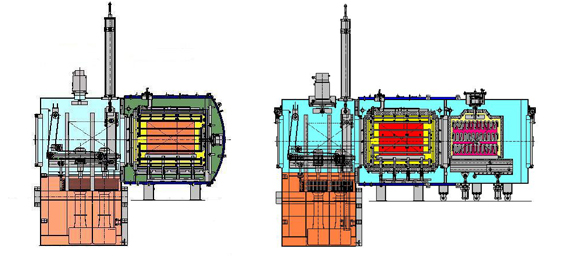

The CaseMaster Evolution has been designed using state of the art construction, with processing chamber & loading vestibule, incorporating a quench tank. Cooling may be carried out in two ways: under neutral gas or in hardening oil. Durable graphite insulation and heating elements provide long, reliable service in this heavy-duty furnace designed for industrial applications. The convection heating system ensures rapid and uniform heating of the load at low temperatures also, which shortens the heat-up time. The high efficiency oil agitation system ensures excellent oil penetration through the workload which results in uniform and fast charge cooling. The gas system, pump system, power supply and cooling systems are generously sized to enable a wide range of industrial heat treatment implementations.

D type – double chamber for batch (In & Out) work processing Oil quench or 1.5 bar (positive pressure) gas pre-cooling T type – triple chamber for continuous work flow with a separate chamber dedicated separately for: / Pre-heating, pre-oxidation / Pre-heating with pre-nitriding acc. to PreNitLPC® technology / High Pressure Gas Quenching N2/Ar

D type – double chamber for batch (In & Out) work processing Oil quench or 1.5 bar (positive pressure) gas pre-cooling T type – triple chamber for continuous work flow with a separate chamber dedicated separately for: / Pre-heating, pre-oxidation / Pre-heating with pre-nitriding acc. to PreNitLPC® technology / High Pressure Gas Quenching N2/Ar Efficiency & Quality

/ Increased efficiency because of shorter carburizing cycle times as a result of very high carbon transition into the workload & high dissociation rate in the pertinent temperature ranges of up to 1050°C / Greater results repeatability in terms of parts and workloads / No intergranular oxidation because of oxygen-free atmosphere

Environment Impact

/ No CO/CO2 emission / Lack of an atmosphere to utilize / No additional, energy consumable equipment i.e.: Endothermic generator / No need of plant ventilation & air conditioning – less heat losses

Health & Safety

/ No open fire – no exhaust hoods / Clean, non-toxic work environment / Workplace safety improvement due to lack of flammable process gases / Easy & intuitive process control / Visual display of the process parameters / No furnace idling periods, quick start up & shut off of the furnace / No special “furnace shutting down” procedures – Just Shut & Go / Process flexibility

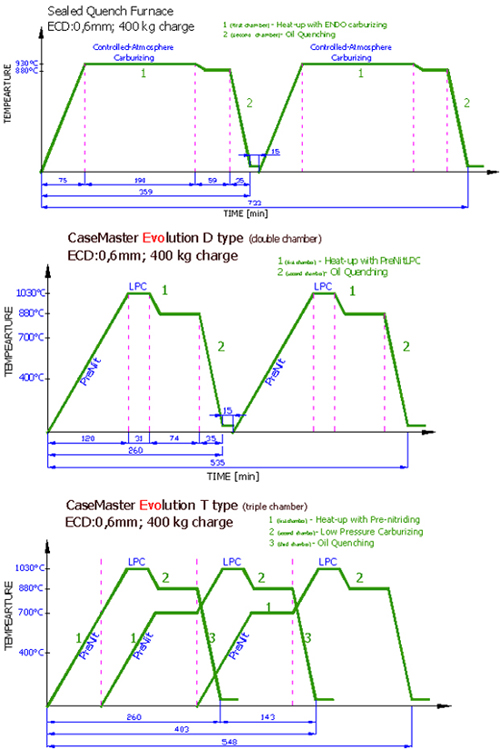

Test Results: Atmosphere Quench vs CaseMaster Evolution

| Material:16MnCr5; netto 400 kg charge; 30 days; 3 shifts; Total proces – carburizing & oil quenching. |

|

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Charge: 600x600x900 [mm] | Temperature [°C] | Total Proces Time [min] | ||||||||

| Sealed Quench Controlled-Atmosphere carburizing | at 935 | 359 | 455 | 600 | ||||||

| No of processes / month | 120 | 95 | 72 | |||||||

| CaseMaster Evolution D9 PreNitLPC carburizing | at 1030 | 260 | 299 | 353 | ||||||

| No of processes / month | 166 | 144 | 122 | |||||||

| CaseMaster Evolution T9 PreNitLPC carburizing | at 1030 | 143 | 179 | 233 | ||||||

| No of processes / month | 306 | 240 | 185 | |||||||

| Efficiency increase referring to CMe D9 | 84% | 66% | 51% | |||||||

| Efficiency increase referring to Sealed Quench | 155% | 153% | 156% | |||||||

Tab. 1 Efficiency increase depending on the furnace type (conventional Sealed Quench, CaseMaster Evolution D – double chamber & T – triple with pre-heating chamber) and applied carburizing technology (Controlled-Atmosphere, PreNitLPC®) for the most typical case depth.

Fig. 1 Capacity increase in comparison of furnace type: (two chamber Sealed Quench furnace, two chamber CMe D type furnace and three chamber CMe T type furnace; for the typical heat treatment process of 16MnCr5 steel when carburized for 0,6 mm ECD) and applied technology (Control-Atmosphere & PreNitLPC).

Applicable for heat processing requiring

/ high-speed & economical process performance / high quality parts following heat treatment

Main technical data for standard applications

| Type | Size | H [mm] | W [mm] | L [mm] | Charge [kg] | Power [kW] |

|---|---|---|---|---|---|---|

| D/T | 6 | 400 | 400 | 600 | 200 | 70 |

| D/T | 9 | 600 | 600 | 900 | 600 | 150 |

| D/T | 12 | 900 | 800 | 1200 | 1200 | 240 |

| D/T | 15 | 1000 | 1000 | 1500 | 2000 | 340 |

Customized version can be produced to the furnace dimensions requested by customer.

DOWNLOAD

Advanced technology uses high temperature and low pressure carburizing to replace conventional sealed quench furnaces by achieving shorter cycle times and higher production rates